The Leeb GS:

Engineering for professionals

The basis

- Solidly designed frame made of quality steel

- Optional: air-suspended axles with level compensation

- Solid drawbar connection for large clearance with standard lower linkage in a trailer hitch ball

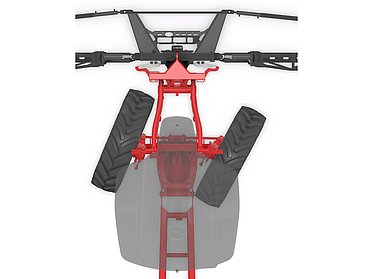

Steering axle – less tramline damage (optional)

- Steering axle for stable positioning of the boom with high stability and exact tracking to avoid tramline damage

- Optimal, even in uneven terrain

- Large steering angle due to a taper-cut frame design

Large tyres – less ground pressure

- Wheels with diameter of up to 2.05 m

- Maximum ground contact area with perfectly adapted air pressure

- Adapted Tyre Pressure Control – automatic tyre pressure regulation that is completely integrated in the software

Extremely low centre of gravity

- Due to the special frame design the tank reaches down below the frame height – high stability at high operational speeds and on slopes

- Minimum residual quantities of chemicals

Taking care of the crop

- Smooth machine underbody

- No edges and corners on the underside of the machine

- Hydraulically foldable and fully covered support leg

Stainless steel tank

- No compromises – high-quality and durable stainless steel tank

- Easy cleaning and residue-free inside walls

- No spraying mixture residues on the absolutely smooth inside wall

- Welded from inside and outside

- Three baffle walls keep the machine steady, even in hilly terrain and during fast road travel

- Round tank for low surging forces

- 500 litre fresh water tank: enough water for one complete inside cleaning. This quantity is enough due to the low quantity of residues in the system.

Three equipment versions

Eco

- Manual operation for the suction and pressure side

- Piston diaphragm pump (400 l/min) driven by pto-shaft

- Hydraulic agitator

CCS

- Manual operation for the suction and pressure side

- Additional piston diaphragm pump for the continuous inside cleaning system CCS

- Continuous inside cleaning can be operated in the cabin

- Oil-driven (Load Sensing) centrifugal pump (1 000 l/min)

- Hydraulic agitator

CCS Pro

- Electronic operation on pressure and suction side for complete control from the cabin

- Additional piston diaphragm pump for the continuous inside cleaning system CCS with automatic washing programs, e. g. intensive washing program, boom rinsing

- Oil-driven (Load Sensing) centrifugal pump (1 000 l/min)

- External control terminal

- Automatic switch-off if the residual quantity in the mixture tank falls below 150 liter.

Theodor Leeb ”The development of the GS line is based on the combination of the requirements of our customers with regard to practice-oriented equipment lines and our wellproven stainless steel tank and the powerful BoomControl system. Efficient plant protection, reliability and efficiency are the basis for our development.”

Leeb GS details

- Tank capacities: 6 000, 7 000 and 8 000 litre

- Low gravity centre of the spraying tank

- Stainless steel tank welded from inside and outside

- Optimised tank shape for transport and cleaning

- Optimised hose laying reduces hose lengths to a minimum

- Boom suspension is designed as a parallelogram – hydr. spring-loaded and damped.

- Soft and smooth boom rest even in hilly terrain and at high operational speeds.

- The geometry of the parallelogram has been designed in such a way that the boom is kept close to the axle. The suspension is extremely torsion-resistant and thus perfectly suitable for the automatic boom controlsystem Leeb BoomControl.

- Nozzle protection againt mechanical damage of the nozzles and wind protection during the development of the spraying fan

Strong, convincing arguments

- Less drift and high working speeds due to automatic BoomControl due to low target area distance

- High working speeds due to hydro-pneumatic boom damping

- Complete circulation in stainless steel circulation tubes to the nozzle

- Continuous ground clearance

- Crop protecting, smooth underfloor design

- Large tyres up to ø 2.05 m possible

- Gravity-optimised and waisted frame design for large steering angles

- Novel operating concept

- Central arrangement of control units

- Pumping capacity up to 1 000 l / min

- Efficient induction hopper made of PE

- Compact external dimensions in transport position

- No parts protruding towards the tractor

- Continuous inside cleaning (CCS and CCS Pro)

- Spring-loaded axle

- Integrated overload protection in the boom

- Second pressure filter at the rear in the parallelogram

Option

- Fully integrated axle steering (when reversing automatic centring of the steering axle)

- Induction hopper made of stainless steel

- NightLight: powerful LED spraying cone lighting with washing device

- Pre-field lighting: 2 LED headlights

- Lighting in the working range of the induction hopper

- SectionControl (automatic section control)

- Pneumatic spring-loaded axle

- Hose drum or high-pressure cleaner for outside cleaning

- Extension by 2 sensors for ridge cultures

- Camera system for the area behind the machine

- Drag hose system

- Wind meter

- ATP Control for automatic regulation of the tyre pressure

- AutoSelect, automatic switching between the nozzle levels

- Connect & Fold system to integrate underleaf spraying systems

TECHNICAL SPECIFICATIONS

| HORSCH Leeb GS | 6 GS | 7 GS | 8 GS |

| Measures and weights | |||

| Curb weight (kg) | 4 950 – 7 200 | 4 950 – 7 200 | 4 950 – 7 200 |

| Tongue load empty (kg) | 700 – 1 200 | 700 – 1 200 | 700 – 1 200 |

| Max. permissible vertical load (kg) | 4 000 | 4 000 | 4 000 |

| Axle load empty (kg) | 4 250 – 6 000 | 4 250 – 6 000 | 4 250 – 6 000 |

| Max. permissible axle load (kg) | 10 000 | 10 000 | 10 000 |

| Overall length max. (transport position) (m) | 8,30 | 8,30 | 8,30 |

| Transport width (transport position) (m) | 2,55 – 3,00 | 2,55 – 3,00 | 2,55 – 3,00 |

| Transport height (m) | 3,40 – 3,60 | 3,40 – 3,60 | 3,40 – 3,60 |

| Track widths (m) | 1,80* / 2,00 / 2,25 | 2,00 / 2,25 | 2,00 / 2,25 |

| Ground clearance axle (m) | 0,85 | 0,85 | 0,85 |

| Tank | |||

| Mixture tank nominal capacity (l) | 6 000 | 7 000 | 8 000 |

| Mixture tank actual capacity (l) | 6 400 | 7 400 | 8 400 |

| Fresh water tank (l) | 500 | 500 | 500 |

| Hand wash tank (l) | 15 | 15 | 15 |

| Spraying boom | |||

| Working widths | 18 / 12 5 sect. | 18 / 12 5 sect. | 18 / 12 5 sect. |

| 21 / 12 5 sect. | 21 / 12 5 sect. | 21 / 12 5 sect. | |

| 24 / 12 5 sect. | 24 / 12 5 sect. | 24 / 12 5 sect. | |

| 27 / 21 / 12 7 sect. | 27 / 21 / 12 7 sect. | 27 / 21 / 12 7 sect. | |

| 28 / 21 / 12 7 sect. | 28 / 21 / 12 7 sect. | 28 / 21 / 12 7 sect. | |

| 30 / 21 / 12 7 sect. | 30 / 21 / 12 7 sect. | 30 / 21 / 12 7 sect. | |

| 30 / 24 / (12) 7 sect. | 30 / 24 / (12) 7 sect. | 30 / 21 / (12) 7 sect. | |

| 32 / 24 / (12) 7 sect. | 32 / 24 / (12) 7 sect. | 32 / 24 / (12) 7 sect. | |

| 33 / 24 / (12) 7 sect. | 33 / 24 / (12) 7 sect. | 33 / 24 / (12) 7 sect. | |

| 36 / 24 / (12) 7 sect. | 36 / 24 / (12) 7 sect. | 36 / 24 / (12) 7 sect. | |

| 38 / 27 / (14) 7 sect. | 38 / 27 / (14) 7 sect. | 38 / 27 / (14) 7 sect. | |

| 39 / 27 / (14) 7 sect. | 39 / 27 / (14) 7 sect. | 39 / 27 / (14) 7 sect. | |

| 40 / 27 / (14) 7 sect. | 40 / 27 / (14) 7 sect. | 40 / 27 / (14) 7 sect. | |

| 40 / 28 / (14) 7 sect. | 40 / 28 / (14) 7 sect. | 40 / 28 / (14) 7 sect. | |

| 42 / 28 / (14) 7 sect. | 42 / 28 / (14) 7 sect. | 42 / 28 / (14) 7 sect. | |

| 44 / 30 / (14) 7 sect. | 44 / 30 / (14) 7 sect. | 44 / 30 / (14) 7 sect. | |

| 45 / 30 / (14) 7 sect. | 45 / 30 / (14) 7 sect. | 45 / 30 / (14) 7 sect. | |

| Sections, min. max. (pieces) | 6 – 42 | 6 – 42 | 6 – 42 |

| Working height (m) | 0.3 – 2.5** | 0.3 – 2.5** | 0.3 – 2.5** |

| Pump output CCS and CCS Pro (l/min) | 1 000 | 1 000 | 1 000 |

| Pump output Basic (l/min) | 400 | 400 | 400 |

| Working pressure, max. (bar) | 8 | 8 | 8 |

| Working speed (km/h) | 4 – 20 | 4 – 20 | 4 – 20 |

* Only possible for Leeb 6 GS track width 1.80 m

** Working height depends on the height of the coupling point on the tractor and the tyres

| HORSCH Leeb GS | 6 GS | 7 GS | 8 GS |

| Spraying boom | |||

| Working widths | 18 / 12 5 sect . | 18 / 12 5 sect . | 18 / 12 5 sect . |

| 21 / 12 5 sect . | 21 / 12 5 sect . | 21 / 12 5 sect . | |

| 24 / 12 5 sect . | 24 / 12 5 sect . | 24 / 12 5 sect . | |

| 27 / 21 / 12 7 sect . | 27 / 21 / 12 7 sect . | 27 / 21 / 12 7 sect . | |

| 28 / 21 / 12 7 sect . | 28 / 21 / 12 7 sect . | 28 / 21 / 12 7 sect . | |

| 30 / 21 / 12 7 sect . | 30 / 21 / 12 7 sect . | 30 / 21 / 12 7 sect . | |

| 30 / 24 / (12) 7 sect . | 30 / 24 / (12) 7 sect . | 30 / 21 / (12) 7 sect . | |

| 32 / 24 / (12) 7 sect . | 32 / 24 / (12) 7 sect . | 32 / 24 / (12) 7 sect . | |

| 33 / 24 / (12) 7 sect . | 33 / 24 / (12) 7 sect . | 33 / 24 / (12) 7 sect . | |

| 36 / 24 / (12) 7 sect . | 36 / 24 / (12) 7 sect . | 36 / 24 / (12) 7 sect . | |

| 38 / 27 / (14) 7 sect . | 38 / 27 / (14) 7 sect . | 38 / 27 / (14) 7 sect . | |

| 39 / 27 / (14) 7 sect . | 39 / 27 / (14) 7 sect . | 39 / 27 / (14) 7 sect . | |

| 40 / 27 / (14) 7 sect . | 40 / 27 / (14) 7 sect . | 40 / 27 / (14) 7 sect . | |

| 40 / 28 / (14) 7 sect . | 40 / 28 / (14) 7 sect . | 40 / 28 / (14) 7 sect . | |

| 42 / 28 / (14) 7 sect . | 42 / 28 / (14) 7 sect . | 42 / 28 / (14) 7 sect . | |

| 44 / 30 / (14) 7 sect . | 44 / 30 / (14) 7 sect . | 44 / 30 / (14) 7 sect . | |

| 45 / 30 / (14) 7 sect . | 45 / 30 / (14) 7 sect . | 45 / 30 / (14) 7 sect . | |

| Sections, min. / max. (pieces) | 6 – 42 | 6 – 42 | 6 – 42 |

| Working height (m) | 0.3 – 2.5* | 0.3 – 2.5* | 0.3 – 2.5* |

| Pump output CCS and CCS Pro (l/min) | 1 000 | 1 000 | 1 000 |

| Max. discharge at the boom for CCS and CCS Pro (l/min) | 350** | 350** | 350** |

| Pump capacity Basic (l/min) | 400 | 400 | 400 |

| Max. discharge at the boom for Basic (l/min) | 300** | 300** | 300** |

| Working pressure, max. (bar) | 8 | 8 | 8 |

| Working speed (km/h) | 4 – 20 | 4 – 20 | 4 – 20 |

* Working height depends on the height of the coupling point of the tractor and the tyres

** The indicated application rates apply to water with a spraying pressure of approx. 5 bar. With other pressures the application rates may differ upward and downward.