The Maestro SV/SX excels due to its well-proven, distinctive seed wagon concept, its universal suitability for all crops as well as the reliable, precise singulation and easy operation.

- Precise and simple singulation of all crops with HORSCH AirVac or AirSpeed

- Operational speed up to 12 km/h possible with AirVac, up to 15 km/h with AirSpeed

- AutoForce for optimum embedding of the grain and regular emergence even in changing soil conditions

- Underground fertilisation with single disc fertiliser coulter or double disc fertiliser coulter

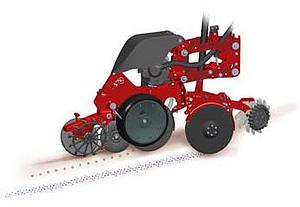

- Conventional use after plough, mulch seed or direct seed

TECHNICAL SPECIFICATIONS

| HORSCH Maestro SV/SX | 12 SV | 16 SV | 18 SV | 24.50 SV | 24 SV | 36 SV | 12 SX | 16 SX | 18 SX | 24.50 SX | 24 SX |

| Transport width (m) | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 |

| Transport height (m) | 4,00 | 4,00 | 4,00 | 4,00 | 4.16 (with micro-granular compound placement ON row 4.25) | 4.16 (with micro-granular compound placement ON row 4.25) | 4,00 | 4,00 | 4,00 | 4,16 (with micro-granular product on the row 4.25) | 4.16 (with micro-granular compound placement ON row 4.25) |

| Transport length (m) | 7,80 | 7,80 | 7,80 | 7,80 | 9,50 | 9,60 | 7,80 | 8,90 | 7,80 | 7,80 | 9,50 |

| Weight incl. seed wagon (kg) | --- | --- | --- | 15500 | 13000 | 15500 | --- | --- | --- | --- | 13000 |

| Axle load (kg) | 7000 - 8700 | 7400 - 9000 | 7800 - 10000 | 8600 - 10800 | 10000 | 11400 | 7000 - 8700 | 7400 - 9000 | 7800 - 10000 | 10000 - 10500 | 10000 |

| Vertical load (kg) | 1500 - 2400 | 1600 - 3000 | 1000 - 2200 | 2000 - 3000 | 3000 | 4100 | 1500 - 2400 | 1600 - 3000 | 1000 - 2200 | 2000 - 3000 | 3000 |

| Hopper capacity seed waggon seed/fertiliser version 1 (l) | 2200 / 5400 | 2200 / 5400 | 2200 / 5400 | 2200 / 5400 | 2000 / 7000 | 2000 / 7000 | 2200 / 5400 | 2200 / 5400 | 2200 / 5400 | 2200 / 5400 | 2000 / 7000 |

| Hopper capacity seed waggon seed/fertiliser version 2 (l) | 3800 / 3800 | 3800 / 3800 | 3800 / 3800 | 3800 / 3800 | 4000 / 5000 | 4000 / 5000 | 3800 / 3800 | 3800 / 3800 | 3800 / 3800 | 3800 / 3800 | 4000 / 5000 |

| Feed opening seed waggon seed (mm) | 800 x 660 (Version 1) | 800 x 660 (Version 1) | 800 x 660 (Version 1) | 800 x 660 (Version 1) | 800 x 660 (Version 1) | 800 x 660 (Version 1) | 800 x 660 (Version 1) | 800 x 660 (Version 1) | 800 x 660 (Version 1) | 800 x 660 (Version 1) | 800 x 660 (Version 1) |

| Feed opening seed waggon fertiliser (mm) | 2450 x 660 (Version 1) | 2450 x 660 (Version 1) | 2450 x 660 (Version 1) | 2450 x 660 (Version 1) | 2450 x 660 (Version 1) | 2450 x 660 (Version 1) | 2450 x 660 (Version 1) | 2450 x 660 (Version 1) | 2450 x 660 (Version 1) | 2450 x 660 (Version 1) | 2450 x 660 (Version 1) |

| Feed opening seed waggon seed/fertiliser (mm) | 1680 x 660 (2 x, Version 2) | 1680 x 660 (2 x, Version 2) | 1680 x 660 (2 x, Version 2) | 1680 x 660 (2 x, Version 2) | 1680 x 660 (2 x, Version 2) | 1680 x 660 (2 x, Version 2) | 1680 x 660 (2 x, Version 2) | 1680 x 660 (2 x, Version 2) | 1680 x 660 (2 x, Version 2) | 1680 x 660 (2 x, Version 2) | 1680 x 660 (2 x, Version 2) |

| Number of rows | 12 | 16 | 18 | 24 | 24 | 36 | 12 | 16 | 18 | 24 | 24 |

| Electrics. Coulter pressure adjustment. terminal (kg) | 150 - 350 | 150 - 350 | 150 - 350 | 150 - 350 | 150 - 350 | 150 - 350 | 150 - 350 | 150 - 350 | 150 - 350 | 150 - 350 | 150 - 350 |

| Depth control wheel Ø (cm) | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Press wheels Ø (cm) | 30 / 33 | 30 / 33 | 30 / 33 | 30 / 33 | 30 / 33 | 30 / 33 | 30 / 33 | 30 / 33 | 30 / 33 | 30 / 33 | 30 / 33 |

| Catching roller | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Row spacing (cm) | 75 | 75 | 45 / 50 | 45 / 50 | 70 / 75 | 45 / 50 | 70 / 75 | 70 / 75 | 45 / 50 | 45 / 50 | 70 / 75 |

| Sowing depth (cm) | 1,5 - 9 | 1,5 - 9 | 1,5 - 9 | 1,5 - 9 | 1,5 - 9 | 1,5 - 9 | 1,5 - 9 | 1,5 - 9 | 1,5 - 9 | 1,5 - 9 | 1,5 - 9 |

| Drop height seed (cm) | 45 | 45 | 45 | 45 | 45 | 45 | --- | --- | --- | --- | --- |

| Tyre size seed waggon | 520 / 85 R 38, optional 580/70 R 38 | 520/85 R 38, optional 580/70 R 38 | 520/85 R 38; 580/70 R 38; 800/65 R 32; twin tyres 300/95 R 46 | 580/70 R 38 or twin tyres 300/95 R 46 | 520/85 R 42 | 520/85 R 42 or twin tyres 320/90 R 54 | 520/85 R 38 or 580/70 R 38 | 520/85 R 38 or 580/70 R 38 | 520/85 R 38 or 580/70 R 38 or twin tyres 300/95 R 46 | 580/70 R 38 or twin tyres 300/95 R 46 | 520/85 R 42 |

| Telescopic axle | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standart | Standard |

| Operational speed (km/h) | 2 - 12 | 2 - 12 | 2 - 12 | 2 - 12 | 2 - 12 | 2 - 12 | 6 - 15 | 6 - 15 | 6 - 15 | 6 - 15 | 6 - 15 |

| Horsepower requirement (kW/hp) | 147 / 200 | 160 / 220 | 160 / 220 | 220 / 300 | 257 / 350 | 257 / 350 | 162 / 220 | 184 / 250 | 184 / 250 | 257 / 350 | 294 / 400 |

| Depressurized return flow (max. 5 bar) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| DA control devices direct drive | 1 DA hydr. functions, 1 DA hydr. fan direct drive underpressure with adjustable flow rate, 1 DA hydr. fan direct drive fertiliser and seed with adjustable flow rate, 1 DA hydr. filling auger fertiliser system | 1 DA hydr. functions, 1 DA hydr. fan direct drive underpressure with adjustable flow rate, 1 DA hydr. fan direct drive fertiliser and seed with adjustable flow rate, 1 DA hydr. filling auger fertiliser system | 1 DA hydr. functions, 1 DA hydr. fan direct drive underpressure with adjustable flow rate, 1 DA hydr. fan direct drive fertiliser and seed with adjustable flow rate, 1 DA hydr. filling auger fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, low pressure with adj. flow rate 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. fan - direct drive, seed with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, low pressure with adj. flow rate 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. fan - direct drive, seed with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, low pressure with adj. flow rate 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. fan - direct drive, seed with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, high pressure a. seed with adj. flow rate 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, high pressure a. seed with adj. flow rate 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, high pressure a. seed with adj. flow rate 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, high pressure a. seed with adj. flow rate 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, high pressure a. seed with adjustable flow rate 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. filling auger, fertiliser system |

| DA control devices pto-shaft drive | 1 DA hydr. functions 1 DA hydr. fan - direct drive, low pressure with adjustable flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, low pressure with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, low pressure with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, seed with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, seed with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, seed with adj. flow rate 1 DA hydr. filling auger, fertiliser syste | 1 DA hydr. functions 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. filling auger, fertiliser system | 1 DA hydr. functions 1 DA hydr. fan - direct drive, fertiliser with adj. flow rate 1 DA hydr. filling auger, fertiliser system | --- | --- |

| Oil quantity hydr. fan fertiliser without micro-granular compound device (l/min) | --- | --- | --- | 60 | 60 | --- | --- | --- | --- | 60 | 60 |

| Oil quantity hydr. fan fertiliser with micro-granular compound device (l/min) | --- | --- | --- | 75 | 75 | --- | --- | --- | --- | 75 | 75 |

| Oil quantity hydr. fan fertiliser (l/min) | --- | --- | --- | --- | --- | 65 | 50 | 50 | 50 | --- | --- |

| Oil quantity hydr. fan seed (l/min) | --- | --- | --- | 20 | 20 | 20 | --- | --- | --- | --- | --- |

| Oil quantity hydr. fan fertiliser/seed (l/min) | 50 | 50 | 50 | --- | --- | --- | --- | --- | --- | --- | --- |

| Oil quantity hydr. fan overpressure/seed (l/min) | --- | --- | --- | --- | --- | --- | 60 | 70 | 70 | 80 | 80 |

| Oil quantity hydr. fan vacuum (l/min) | 25 | 25 | 25 | 55 | 55 | 55 | --- | --- | --- | --- | --- |

| Oil quantity min. lift/lower (l/min) | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Power requirement in operation (Ampere) | 45 | 50 | 50 | 60 | 65 | 80 | 45 | 50 | 50 | 60 | 65 |

| Implement attachment adjustable drawbar | Ring hitch Ø 58/79 mm | Ring hitch Ø 58/79 mm | Ring hitch Ø 58 / 79 mm | Ring hitch Ø 58 - 79 mm | Ring hitch Ø 58 - 79 mm | Ring hitch Ø 58 - 79 mm | Ring hitch Ø 58 - 79 mm | Ring hitch Ø 58 - 79 mm | Ring hitch Ø 58 - 79 mm | Ring hitch Ø 58 - 79 mm | Ring hitch Ø 58 - 79 mm |

| Implement attachment ball head | K 80 | K 80 | K 80 | K 80 | K 80 | K 80 | K 80 | K 80 | K 80 | K 80 | K 80 |

Features

AirVac and AirSpeed

Versatile - Precise - Efficient

Advantages at a glance:

- Can be used universally for different crops

- Easy handling: no adjustment of the singulator required

- Reliable singulation of different grain sizes

- Electric drive as a basis for: SectionControl, VariableRate, tramline control

AirVac:

- Operational speeds up to 12 km/h

- Utmost flexibility for all crops and optimum embedding of the grain

AirSpeed:

- Operational speeds up to 15 km/h

- Maximum efficiency with safe embedding of the grain

The new metering generations AirVac and AirSpeed basically have a very similar design. They work according to the same metering principle. They can be used universally for a very precise grain singulation for a lot of crops. With different metering discs maize, sunflowers, sugar beet, soyabeans and other bean crops as well as rape and sorghum are singulated reliably.

The AirSpeed system works according to the overpressure principle where the grains are pressed to the perforated disc. The AirSpeed system works according to the overpressure principle where the grains are pressed to the perforated disc. In both metering devices, the grains run through a singulator which sees to it that double seed is avoided. The characteristic of this special component is that it does not have to be replaced when changing crops and that the driver does not have to carry out any adjustments. The contour of the singulator was optimised in such a way that a reliable singulation for all crops is guaranteed.

The basic difference between the two new metering generations is the transfer of the seed from the metering device into the soil: with the AirVac system, after the singulation the seed is led into the bottom of the furrow by means of the drop tube and if required is pressed by the catching roller. With the AirSpeed system the singulated grains are captured by an air current, accelerated and shot with the air current through the shoot pipe into the soil. They are caught and embedded by the mounted catching roller.

In both metering devices the grains pass a grain sensor in the drop - shoot tube for an optimum monitoring of the sowing success. The measurement technology of the sensor is able to count grains, identify spacings between the grains and thus inform the driver about double spots and gaps.

The transferred values of the singulation accuracy are clearly displayed at the terminal of the machine and additionally increase safety for sowing. The new metering generations AirVac and AirSpeed are driven electrically as standard, and each row can be controlled individually. This technology allows for the well-known functions individual row switch-off, SectionControl, VariableRate and tramline control.

For VariableRate the metering systems have been designed in such a way that the seed quantity can be changed individually for each row. With regard to the tramline control the sowing density can be adapted individually in the rows at the left and at the right side of the tramline. With these advanced functions all measures to increase precision while sowing can be used to full capacity.

Tyre options

Large tyres for wide row spacings:

- 520/85 R 38

- 580/70 R 38

- 520/85 R 42

Optional twin tyres for a row spacing of 45 and 50 cm:

- 300/95 R 46

- 320/90 R 54

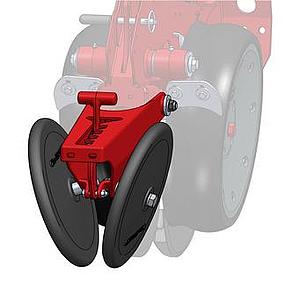

Double disc fertiliser coulter

Only for AirVac

- Attachment and depth control of the fertiliser coulter via the flange plate on the row unit

- Placement of the fertiliser on the same level as the grains or at 3 or 5 cm below the seed depth

- Coulter pressure for the fertiliser coulter is generated by the hydraulic cylinder of the row unit

- Only available for Maestros with AirVac metering

In addition to a precise placement of the grains the exact positioning of fertilisers or plant protection agents is very important for single grain sowing. The rows of the Maestros, thus, can be equipped with different components to provide an optimum solution for all requirements and demands.

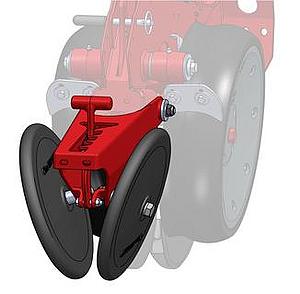

SingleDisc fertiliser coulter

- The SingleDisc fertiliser coulter is suspended independently of the seed row

- The placement depth can be set to 5 to 9 cm

- Quick adaption of the coulter pressure without tools from 40 to 140 kg

- Deactivation is possible without tools by lifting the unit out of work

In addition to a precise placement of the grains the exact positioning of fertilisers or plant protection agents is very important for single grain sowing. The rows of the Maestros, thus, can be equipped with different components to provide an optimum solution for all requirements and demands.

Additional Features

Press wheels

For a better embedding of the grains

Which press wheel is suitable for which application?

Rubber and profiled press wheel

- Rubber closing wheels for light sandy conditions

- The profiled wheels are recommended for fine seeds.

- The profile additionally creates fine earth and can better prevent silting.

Finger and spike press wheel:

- The finger press wheel is ideal for heavy and medium soils

- Spike press wheel for medium to light sites

- There is one finger / spike wheel and one standard wheel per row to control the depth and to avoid moving the grains.

- However, the wheels are not suitable for shallow sowing.

- If the furrow wall gets compacted because of the DoubleDisc seed coulters, it is broken by the finger / spike wheel – the furrow is removed.

- Seed furrow is not opened after sowing under dry conditions, especially on heavy clayey sites

- Development of the maize root is encouraged

The closing of the seed furrow is the last time when you can influence emergence. Depending on the type of soil, the sowing method, sowing depth and the crop, the requirements differ. Therefore, the Maestros can be equipped with different press wheels and press wheel combinations to be able to achieve an optimum work result for all crops in all conditions.

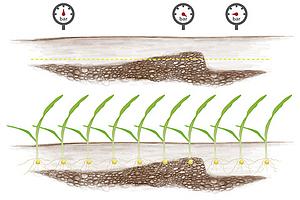

AutoForce

Optimum embedding despite changing soil conditions

What do you need an automatic coulter pressure control for?

- Stony soils require more coulter pressure to place the seed at a consistent depth. If the coulter pressure is too low the coulter body would not move smoothly and the seed would germinate irregularly and with different speed.

- Light conditions or pressure-sensitive soils need less coulter pressure so that the soil is not compacted. Too much coulter pressure compacts the soil and slows down the development of the roots although all seed was placed at the same depth.

- There rarely are fields that are completely even. The coulter pressure has to be adapted to each section of the field.

- This is why AutoForce has been available for the Maestro line since 2016.

AutoForce guarantees an always consistent embedding of the grains in changing conditions. Thus, more regular emergence and populations are achieved. The contact pressure of the row unit is measured with a sensor at the two support wheels. This pressure (= nominal value) is previously set in the terminal. You can choose between three pressure levels: 25 kg – 50 kg and 80 kg (the values can also be adapted individually). With changing soil conditions, the row needs more or less power to be able to keep up the set placement depth. The contact pressure would change. The sensor detects this, and the system regulates the contact pressure in such a way that it always corresponds to the nominal value that has been set. This is possible due to the design of the machine which allows for transferring weight to the seed bar. The coulter pressure automatically varies between 150 kg and 350 kg. Thus, the grain is always embedded at the same level. A too shallow placement as well as soil compaction can thus be avoided.

ContourFarming

Constant seeding rate across the whole working width when cornering

- Adapted seed rate control when cornering

- Control of seed rate via two additional radar sensors

- Recording of inside and outside radius speed

Especially in uneven shaped fields, ContourFarming offers many advantages. For large working widths there is a speed difference between the inside and outside radius of the seed bar. The system measures this difference and adjusts the seed rate by means of a speed change of the metering units proportionally across the working width. Thus, the set seed rate is maintained precisely across all rows.

Press wheel holders

Standard press wheel holder (standard equipment):

- Pressure adjustment in four steps (from 8 to 55 kg)

- Adjustment of the wheel spacing with spacers

- Wheels can be placed in an offset position for a high clearance

Press wheel holder with angle adjustment (option):

- Same adjustment options as for the standard holder

- In addition: six steps for the angle adjustment

- Forming of a ridge as the wheels earth up more soil

- Recommended for fine seeds (sugar beet, rape)

The closing of the seed furrow is the last time when you can influence emergence. Depending on the type of soil, the sowing method, sowing depth and the crop, the requirements differ. Therefore, the Maestros can be equipped with different press wheel holders and press wheel combinations to be able to achieve an optimum work result for all crops in all conditions.

![[Translate to englisch:] [Translate to englisch:]](/fileadmin/_processed_/4/d/csm_19526_180c477f00.jpg)

![[Translate to englisch:] [Translate to englisch:]](/fileadmin/_processed_/2/2/csm_18465_791b6fd00a.jpg)