Cruiser 4 / 5 / 6 SL

THE SEEDBED PERFECTIONIST

What are the excelling features of the Cruiser SL?

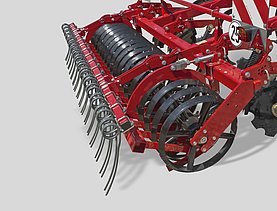

The cultivator Cruiser SL is the new specialist for shallow tillage with 3-point linkage. It is available in 4, 5 and 6 metre working width. With a maximum working depth of 15 cm it is ideal for perfect stubble cultivation with optimum straw distribution after combine harvesting, for seedbed preparation, as a fine cultivator for mechanical weed control and for loosening and venting the soils in spring.

Due to its 4-bar design the levelling effect of the Cruiser is excellent. Due to the special design of the tine above the frame the clearance amounts to 70 cm, thus increasing the clearance in the fine cultivator sector considerably. The close tine spacing of 16 cm guarantees an optimum mixing ratio and a perfect crumbling on the surface.

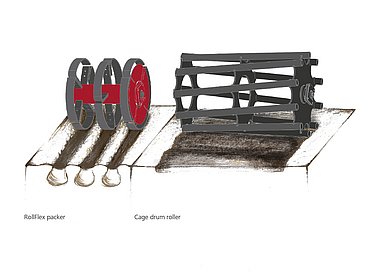

The new RingFlex packer is another upgrade for out Cruiser SL . Due to its 7-cm-wide rings the contact area is larger. Thus, it allows for an exact depth control even in lighter soils. Moreover, it produces a high amount of fine soil which is optimum for the emergence of the following crop.

RollFlex packer

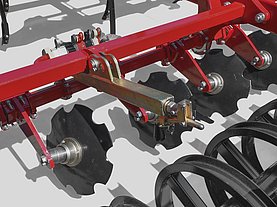

HORSCH spring tine in the new Cruiser SL

Hydraulic depth adjustment with display

Optional: disc levelling or tine levellers

Cruiser SL

Shallow cultivation

in perfection

- Specialist for shallow tillage with 3-point linkage in 4, 5 and 6 m working width

- Perfect stubble cultivation with optimum straw distribution at a maximum working depth of 15 cm

- The narrow tine spacing of 16 cm guarantees an optimum mixing ratio and a perfect crumbling on the surface

- Different packers that are adapted to the respective site guarantee an exact depth control and produce a high quantity of fine earth

TECHNICAL SPECIFICATIONS

| HORSCH Cruiser SL | 4 SL | 5 SL | 6 SL |

| Working width (m) | 4.00 | 4.96 | 5.92 |

| Transport width (m) | 2.94 | 2.94 | 2.94 |

| Transport height (m) | 2.30 | 2.70 | 3.20 |

| Length (m) | 4.30 | 4.30 | 4.30 |

| Weight (kg)* | 2 200 – 2 700 | 2 500 – 3 300 | 3 000 – 3 600 |

| Number of tines | 25 | 31 | 37 |

| Tine spacing in one row (cm) | 64 | 64 | 64 |

| Tine spacing (cm) | 16 | 16 | 16 |

| Maximum working width (cm) | 15 | 15 | 15 |

| Actual clearance (mm) | 700 | 700 | 700 |

| DA control devices | 1 (+1 hydr. depth adjustment) | 1 (+1 hydr. depth adjustment) | 1 (+1 hydr. depth adjustment) |

| Horsepower requirement (kW/hp) | 90 – 120 / 140 – 190 | 110 – 150 / 170 – 230 | 130 – 180 / 200 – 270 |

| Tool attachment | 3-point Cat. III | 3-point Cat. III | 3-point Cat. III |

* Weight of the machines with minimum / maximum equipment

Features

HORSCH spring tines

Elegance meets power

To meet the requirement of flexible use for a tillage tool, new technologies and developments in this sector are essential. A tool for stubble cultivation needs a powerful tine that distributes harvest residues in an optimum way and guarantees good mixing. For seedbed preparation in the spring the farmer expects the highest precision with regard to levelling and at the same time high stability to break the topsoil from the winter furrow. HORSCH combines all these characteristics in a new generation of tines.

With a release force of 150 kg and a trip release height of 20 cm the HORSCH spring tine constantly maintains the promised work-ing depth of up to 15 cm even in the most difficult conditions. Due to the novel design of the spring tine the clearance of the Cruiser SL is increased from 600 mm to 700 mm. This allows for working without blocking even if there are high quantities of organic residues.

The special geometry of the suspension of the new HORSCH spring tine allows for an easy upward release without a lot of movement in the spring. This novel technology eases the stress on the material and increases the service life considerably.

To achieve the best work result, HORSCH offers the appropriate point version for the new HORSCH spring tine for any use – from a 5 cm wide chisel point for seedbed preparation to a carbide duck foot point for an all-over cutting during stubble cultivation.

HORSCH spring tine

High clearance

HORSCH spring tine

HORSCH

Point versions for any use

Due to the many point versions the HORSCH Cruiser can be used almost the whole year – for a ventilation of the soil in spring, for seedbed preparation for maize, for stubble breaking in summer and for seedbed preparation in autumn. The point angle allows for an ultra-shallow and all-over cutting at a low working depth. All point versions are available with the wellproven HORSCH carbide-tipping (HM) for a long service life.

5 cm HM point 5 cm wide HM point: ideal for seedbed preparation and for the ventilation of the soil in spring – up to 15 cm working depth

8 cm HM point 8 cm wide HM point: ideal for stubble breaking, straw distribution and mixing, can also be used for seedbed-preparation – up to 10 cm working depth.

10 cm HM point 10 cm wide HM point: ideal for stubble and seedbed preparation on very light soils, perfect straw distribution and mixing of organic matter – max. working depth up to 10 cm.

Carbide duck foot point Ideal for shallow mechanical weed control, all-over cutting – as of 2 cm working depth.

5 cm HM point

8 cm HM point

10 cm HM point

Carbide duck foot point

Carbide duck foot point

Packer

FOR THE OPTIMUM RESULT

HORSCH offers the appropriate packer version for deep as well as for shallow consolidation. The choice of the packer always depends on the soil and HORSCH has a suitable solution for any type of soil. Consolidation compacts excessively loose soil, crushes clods and creates optimum surroundings with an optimum ratio of water-bearing and air-bearing pores.

The following packers are available for the Cruiser SL:

RollFlex packer, cage drum roller, DoubleCage packer and RingFlex packer.

PACKING SYSTEMS

VERSATILE FOR OPTIMUM RESULTS

RollFlex packer

- Excellent self-cleaning due to vibrating springs

- Strip consolidation

- High mixing effect

- Excellent levelling

Cage drum roller

- Diameter Ø 64 cm

- Leaves a fine-crumbly surface

- Exact depth control

- Flexible operating conditions

RingFlex packer

- Excellent self-cleaning effect due to the inherent vibration of the leaf springs

- Deep consolidaton due to open packer rings

- Additional mixing effect due to the movement of the soil in the packer

- High fine earth production

- Open packer with intermediate springs for excellent levelling

Why is the appropriate packer important for your machine?

- Central element to determine the working quality

- Depth control

- Different consolidation depending on the requirements

- Perfect working quality in wet and dry conditions

- Appropriate germination bed for volunteer crops and weeds

- Rough, loose soil structure for medium and heavy soils

- Final finishing of the seed horizon

Depth adjustment disc levelling

Cage drum roller

Hydraulic depth adjustment with display

HORSCH spring tine (150 kg release force)

8 adjustable edge discs Cruiser SL

Optional harrow behind the packer

Leveller levelling

LED rear lights

Storage area for hydraulic couplings