Express KR

3-point seed drill with rotary harrow Kredo

What are the outstanding features of the Express KR?

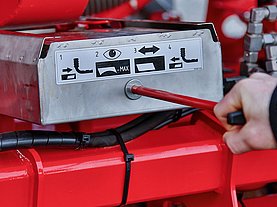

The Express KR combines the well-proven HORSCH seeding technology with pto-shaft driven tillage and the rotary harrow Kredo. Even under difficult conditions it allows for an intensive seedbed preparation. The rotary harrow Kredo has 10 rotating tools on 3 m working width. Its stable design is ideal even on stony soils. With quick-change tines it can be equipped with drag or TerraGrip tines. Tines with carbide coating are available for longest possible service life. The well-proven coating technology from the cultivator tine sector is used. The fine-step adjustment of the working depth of the rotary harrow is easily accessible from the outside and is clearly visible. The adjustment of the levellingbar, too, is very easy.

Three packer versions are available for the Express KR. The tooth packer roller with a large 64 cm diameter is ideal for all conditions. Its load-carrying capacity even on light soils is quite high, thus the consequences on horsepower requirement and diesel consumption are very positive. The trapeze ring packer’s diameter amounts to 50 cm for heavy soils ith a high consolidation in the seeding zone or to 60 cm for changingsoils from light to heavy with high requirements on the load-carrying capacity. It forms a perfect seed furrow even in heavy and cohesive conditions.

The FarmFlex packer is ideal for medium soils with little cohesion. The solid rubber roller with a diameter of 54 cm creates a zone consolidation of the soil in the shape of a furrow and reduces the encrusting effect of the soil (only available for Express 3 KR).

For more flexibility the Express KR is available with single or double hopper. With the double hopper version two components can be metered into the same seed flow and can be placed together in the seed furrow.

The adjustment of the seed discs is made hydraulically and is marked with the well-known coloured AluClips. The Express KR disposes of a frame, so the adjustment of the power harrow does not affect the sowing depth. The TurboDisc seed coulters can be lifted completely hydraulically so you can work solo with the just power harrow. Moreover, the seed unit can easily be uncoupled from the power harrow via only 4 fixing points to be able to use the Kredo solo.

Express KR

3-point seed drill with rotary harrow

- 3-point seed drill for an intensive seedbed preparation even in difficult conditions.

- Three packer versions are available that are suitable for different conditions.

- TurboDisc seed coulters guarantee a perfect seed placement.

- Seed coulters can be lifted completely hydraulically to allow for a solo use of the rotary harrow.

Express 4 KR

What are the excelling features of the Express 4 KR?

In addition to the rigid version, the Express 4 KR now is also available as a folding version. With a transport width of max. 3 metres it can be used very flexibly. The technical equipment is similar to the Express 3 KR and the machine is equipped with either the trapeze ring roller or the tooth packer. The 14 rotors guarantee a perfect seedbed preparation even in most difficult conditions and with an operational speed of up to 13 km/h.

Optimum weight distribution with Partner FT

For an optimum weight distribution the Express 4 KR is combined with the HORSCH Partner FT that is mounted in the front. The latter is available in two versions:

Partner 1600 FT The compact single hopper version Partner 1600 FT guarantees maximum efficiency and a long range for one component. The pressurised hopper in combination with the Express 4 KR can be used for seed and in combination with for example a Maestro RV it can be used to apply fertiliser. Especially in case of high throughput volumes the concept of the pressurised hopper allows for high operational speeds. The Partner 1600 FT with basic equipment weighs 700 kg and can be equipped with an additional weight of 360 kg as an option.

Partner 2000 FT If seed and fertiliser or two different seeds are used, the Partner 2000 FT with double hopper is the perfect choice. The tank with a capacity of 2 200 liter is a pressurised hopper with a partition ratio of 60 : 40 (1 320 : 880 l).

Both Partner FT can be equipped with an intermediate axle packer to guarantee a maximum soil protection.

The double fall sluice at the metering device of the Partner 1600 FT or at the two metering devices of the Partner 2000 FT allows for a half-width shut-off. Beside the manual control, an electrical control of the half-width shut-off is available, too. Via GPS signal, it can be connected with SectionControl to reduce overlapping.

TECHNICAL SPECIFICATIONS

| HORSCH Express | 3 KR | 3.5 KR | 4 KR rigid | 4 KR | 6 KR |

| Working width (m) | 3.00 | 3.50 | 4.00 | 4.00 | 6.00 |

| Transport width (m) | 3.00 | 3.50 | 4.00 | 2.98 | 3.00 |

| Filling height (m) | 2.08 | 2.00 | 2.00 | Partner FT | Partner FT |

| Length without / with PE marker (m) | 2.85 / 3.25 | 2.85 / 3.25 | 2.85 / 3.25 | 3.00 / 3.40 | 3.00 / 3.40 |

| Weight approx. (kg)* | 3 300 – 3 800 | 3 600 – 4 250 | 4 100 – 4 800 | 4 050 – 4 650 | 5 500 |

| Seed hopper capacity single hopper (l) | 1 500 | 1 500 | 1 500 | Partner FT | Partner FT |

| Dimension of feed opening (m) | 0.93 x 2.40 | 0.93 x 2.40 | 0.93 x 2.40 | Partner FT | Partner FT |

| Hopper capacity double hopper G & F (l) | 2 000 (45 : 55) | 2 000 (45 : 55) | 2 000 (45 : 55) | Partner FT | Partner FT |

| Dimension of feed opening (m) | 0.93 x 2.40 | 0.93 x 2.40 | 0.93 x 2.40 | Partner FT | Partner FT |

| Number of seed coulters | 24 (12.50 cm row spacing) / 20 (15.00 cm row spacing) | 24 | 28 | 28 | 48 (12.50 cm row spacing) / 40 (15.00 cm row spacing) |

| Coulter pressure seed coulters (kg) | 5 – 120 | 5 – 120 | 5 – 120 | 5 – 120 | 5 – 120 |

| Seed coulters / press wheels Ø (cm) | 34 / 32 | 34 / 32 | 34 / 32 | 34 / 32 | 34 / 32 |

| Row spacing (cm) | 15.00 | 14.50 | 14.25 (14.50) | 14.50 | 12.50 or 15.00 |

| Packer Ø (cm) trapeze ring roller | 50 / 60 | 50 / 60 | 50 / 60 | 50 / 60 | 50 |

| Packer Ø (cm) tooth packer | 64 | 64 | 64 | 64 | 53 |

| Packer Ø (cm) FarmFlex packer | 54 | --- | --- | --- | 55 |

| Number of rotating tools | 10 | 12 | 14 | 14 | 20 |

| Working speed (km/h) | 6 – 13 | 6 – 13 | 6 – 13 | 6 – 13 | 6 – 13 |

| Power demand (kW/hp) | 110 – 185 / 150 – 250 | 129 – 185 / 175 – 250 | 147 – 185 / 200 – 250 | 147 – 185 / 200 – 250 | 185 – 260 / 250 – 350 |

| DA control devices | 2 (+1 bout marker) | 2 (+1 bout marker) | 2 (+1 bout marker) | 1 (folding), 1 (bout marker), 1 (coulter pressure – SA) | 1 (+1 for bout marker, +1 for pre-emergence marker) |

| Depressurized return flow (max. 5 bar) | 1 | 1 | 1 | Partner FT | Partner FT |

| Oil quantity hydr. fan (l/min) | 20 – 25 | 20 – 25 | 20 – 25 | Partner FT | Partner FT |

| 3-point linkage | 3-point Cat. III | 3-point Cat. III | 3-point Cat. III | 3-point Cat. III | 3-point Cat. III |

* Weight of the empty machines with minimum / maximum equipment

| HORSCH Partner | Partner 1600 FT |

| Transport width (m) | 2.50 |

| Height (m) | 1.56 |

| Length without additional weight (m) | 1.44 |

| Weight without additional weight (kg) | 700 |

| Hopper capacity (l) | 1 600 |

| Dimensions of feed openings (m) | 2.30 x 0.67 |

| Filling height (m) | 1.56 |

| DA control devices | 1 |

| Depressurized return flow (max. 5 bar) | 1 |

| Oil quantity hydr. fan (l/min) | 20 – 35 |

| Tractor-side tool linkage | 3-point Cat. II and III |

| HORSCH Partner | Partner 2000 FT |

| Transport width (m) | 2.71 |

| Height (without / with tyre packer) (m) | 1.65 / 1.90 |

| Length (without / with tyre packer) (m) | 1.66 / 1.70 |

| Weight (without / with additional weight) (kg) | 1 040 / 1 430 |

| Additional weight with tyre packer (kg) | 280 |

| Hopper capacity (l) | 2 200 (partitioned hopper 1 320 : 880 l / 60 : 40 or 1 650 : 550 l / 75 : 25) |

| Dimensions of feed openings (m) | 0.83 x 0.66 (small chamber) / 1.45 x 0.66 (large chamber) |

| Filling height (without / with tyre packer) (m) | 1.57 / 1.82 |

| DA control devices | 1 |

| Depressurized return flow (max. 5 bar) | 1 |

| Oil quantity hydr. fan (l/min) | 20 – 35 |

| Tractor-side tool linkage | 3-point Cat. II and III |