Shallow weed control before sowing, seedbed preparation in spring or in autumn with packer and harrow, shallow and efficient all-over cutting – these are the tasks of the HORSCH Finer SL.

Weed control and seedbed preparation - the Finer SL combines both in one machine

- Ideal to keep the soil brown and for seedbed preparation

- Compact design due to a bar spacing of 50 cm

- All-over cutting due to 22 cm wide wing points and a tine spacing of 15 cm

- Can be used in different situations to meet all requirements.

The HORSCH Finer SL is ideal for shallow tillage at a working depth of up to 10 cm. Its main tasks are to keep the soil surface brown, to remove weeds and grass and to place them loosely on the surface. The Finer can also be used for seedbed preparation.

Which applications has the Finer been designed for?

- Shallow tillage and all-over cutting at a working depth of max. 10 cm

- Uproot and remove soil from weeds and grass

- Seedbed preparation

- Wide range of additional equipment like seed kit and MiniDrill

- Very efficient due to working widths from 5 to 8 m with 3-point linkage

TECHNICAL SPECIFICATIONS

| HORSCH Finer | 5 SL | 6 SL | 7 SL |

| Working width (m) | 5,00 | 6,00 | 7,00 |

| Transport width (m) | 2,70 | 2,70 | 2,70 |

| Tine spacing (cm) | 15.20 | 15.40 | 15.60 |

| Frame height (cm) | 58.50 | 58.50 | 58.50 |

| Transport height (m) | 2,75 | 3,25 | 3,75 |

| Length (m) | 3,00 | 3,00 | 3,00 |

| Weight (kg) | 2 000 | 2 150 | 2 300 |

| Number of tines (PCE) | 33 | 39 | 45 |

| Tine spacing in one row (cm) | 61 | 62 | 62 |

| Tyre size depth control wheels | 23 x 10.5 – 12 | 23 x 10.5 – 12 | 23 x 10.5 – 12 |

| Maximum working depth (cm) | 10 | 10 | 10 |

| DA control devices (Piece) | 1 (+1 depending on option) | 1 (+1 depending on option) | 1 (+1 depending on option) |

| Horsepower requirement (kW/hp) | 90–175 / 120–240 | 115–200 / 160–270 | 130–220 / 180–300 |

| Implement attachment 3-point | Cat. III / IV | Cat. III / IV | Cat. III / IV |

Features

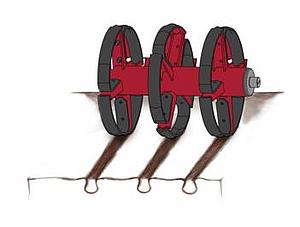

RollFlex packer

- Deep consolidation with loose soil surface

- High levelling capacity due to intermediate levelling tine

- Self-cleaning, without scrapers

- High operational reliability

The RollFlex packer guarantees high reliability on changing soil types even in wet conditions. Due to the deep consolidation, excessively loose soil is compacted, clods are crushed. The result is an optimum environment with the optimum drying conditions.

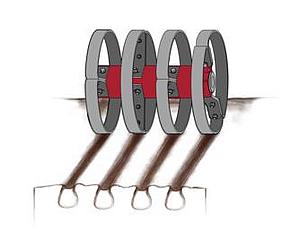

RingFlex packer

- High contact area due to 7 cm wide ring elements

- Additionally mixes in organic material

- Can be converted to a winter packer

- Weight per m working width: 120 kg

The RingFlex packer impresses due to its excellent load-carrying capacity on light and medium soils. Moreover, it guarantees a good consolidation. Depending on the conditions, it can also be used as a winter packer by removing individual rings.

RollPack packer

- Steel ring roller with a diameter of 55 cm

- Deep strip consolidation

- Flexible conditions of use

- Weight per m working width: 125 kg

The RollPack packer is ideal for light and medium sites. Due to the good consolidation and the rigid ring elements the range of use is very wide.

RollCut packer

- Strip consolidation

- Good surface structure on medium, stony soils

- Ideal packer for medium to heavy, stony soils

- Weight per m working width: 130 kg

The RollCut packer is ideal for all heavy and/or stony soils. Due to its cutting rings, it leaves a well consolidated and crumbly surface. Ideal to stimulate the germination of volunteer crops and weeds or for seedbed preparation.

Additional Features

Double spring

Double spring for more directional and height stability of the cultivation tines

- Additional spring with 70 mm*12 mm

- Guarantees higher release forces

- More stable tine control in the soil

- Ideal for dry and hard conditions

The double spring of the Finer SL ensures a higher release force of the tine and more stable position in the soil. The double spring effectively minimises the lateral and the upward deflection.

Seeding kit Finer SL

Seeding kit for sowing with the Finer

- Pneumatic system with tine seed coulters

- Double distribution tower

- Ideal for sowing in wet conditions

The seed kit for the Finer SL is ideal for sowing catch crops and in wet conditions. Depending on the conditions, there are a lot of application options for the Finer.

Four depth control wheels which are mounted at the packer

- 4 depth control wheels can replace the packer

- Quick changing between packer and depth control wheels

- Extended range of applications for Finer SL

Due to the additional depth control wheels for the Finer SL, the packer can easily replaced by depth control wheels. Thus, the Finer SL can either be used for seedbed preparation as well as for weed management.