The HORSCH Tiger MT is ideal for mixing in harvest residues and also for a deep loosening at a depth of 35 cm. It breaks plough pans and at the same time mixes in organic material reliably over the whole cultivation horizon.

A heavy cultivator for deep tillage up to max. 35 cm with a robust design and the objective to perfectly mix in organic material

- Combination of disc system and tine system for high amounts of organic material

- Robust design for hardest conditions and long service life

- Large selection of packer versions for intensive consolidation

- Maintenance-free disc system and TerraGrip tine system with a release force of 770 kg and a very long service life

The HORSCH Tiger MT is ideal when it comes to incorporating a lot of organic material in one pass. The HORSCH Tiger MT is equipped with a 2-row disc system combined with a 2-row tine system. Optimum after sunflowers or grain maize to mix in organic material over the whole working width.

Perfect stubble cultivation

- Tillage at a depth of up to 35 cm and mixing in of organic material over the whole cultivation horizon

- Even mixing of harvest residues, catch crops and organic fertilisers over the whole cultivation horizon

- Combination of disc system and tine system for intensive mixing and high clearance even in case of a lot of organic material

- Wide selection of different packer versions for optimum consolidation

- Additional equipment like fertiliser distributor, MiniDrill and a good deal more

TECHNICAL SPECIFICATIONS

| HORSCH Tiger MT | 3 MT | 4 MT rigid | 4 MT | 5 MT | 6 MT | 8 MT |

| Working width (m) | 3,00 | 4,00 | 4,00 | 4,80 | 6,00 | 7,50 |

| Transport width (m) | 3,00 | 4,05 | 3,00 | 3,00 | 3,00 | 3,00 |

| Transport height (m) | 2,40 | 2,40 | 2,90 | 3,20 | 3,60 | 4,00 / 4,15 (with levelling disc 2-row Ø 46 cm) |

| Length with tyre packer 7.50–16 (m) | 8,30 | 8,60 | 8,60 | 8,60 | 8,60 | 8,60 |

| Length with tyre packer 210 / 95 - 24 (m) | 8,70 | --- | 9,00 | 9,00 | 9,00 | 9,00 |

| Length with double RollPack packer (m) | 9,00 | 9,30 | 9,30 | 9,30 | 9,30 | 9,30 |

| Weight (kg) | 4215 | 5525 | 6575 | 7425 | 8420 | 10380 |

| Number of DiscSystem discs (Piece) | 14 | 18 | 20 | 24 | 28 | 36 |

| Disc spacing (cm) | 38 | 40,5 | 40 | 39 | 42 | 41 |

| Number of tines (Piece) | 7 | 9 | 9 | 11 | 13 | 17 |

| Tine spacing in one row (cm) | 86 | 94 | 94 | 91 | 96 | 90 |

| Tine spacing (cm) | 43 | 47 | 47 | 45,5 | 48 | 45 |

| Frame height (mm) | 850 | 850 | 850 | 850 | 850 | 850 |

| DA control devices lower link | 2 (+1 with marker) | 3 (+1 with marker) | 3 (+1 with marker) | 3 (+1 with marker) | 3 (+1 with marker) | --- |

| DA control devices adjustable drawbar | --- | --- | 4 (+1 with marker) | 4 (+1 with marker) | 4 (+1 with marker) | 4 |

| Horsepower requirement (kW/hp) | 110 - 220 / 150 - 300 | 150 - 270 / 200 - 370 | 150 - 270 / 200 - 370 | 185 - 295 / 250 - 400 | 220 - 400 / 300 - 550 | 275 - 440 / 375 - 600 |

| Tyre packer size / Ø (cm) | 7.50 – 16 AS / 78 cm or 210 / 95 – 24 AS / 100 cm | 7.50 – 16 AS / 78 cm | 7.50 – 16 AS / 78 cm or 210 / 95 – 24 AS / 100 cm | 7.50 – 16 AS / 78 cm or 210 / 95 – 24 AS / 100 cm | 7.50 – 16 AS / 78 cm or 210 / 95 – 24 AS / 100 cm | 7.50 – 16 AS / 78 cm or 210 / 95 – 24 AS / 100 cm |

| Double RollPack packer Ø (cm) | 62 | 62 | 62 | 62 | 62 | 62 |

| Lower link linkage | Cat. III - III / IV - IV | Cat. III - III / IV - IV | Cat. III - III / IV - IV | Cat. III - III / IV - IV | Cat. III - III / IV - IV | Cat. III - III / IV - IV |

| Adjustable drawbar linkage hitch | --- | --- | Bolt Ø 50 mm | Bolt Ø 50 – 70 mm | Bolt Ø 50 – 70 mm | Bolt Ø 70 mm |

| Adjustable drawbar linkage hitch ball joint | --- | --- | Hitch Ø 51 mm | Hitch Ø 51 – 71 mm | Hitch Ø 51 – 71 mm | Hitch Ø 71 mm |

| Adjustable drawbar linkage ball head | --- | --- | K 80 | K 80 | K 80 | K 80 |

Features

TerraGrip III

Robust reliability

- Release force from 500 to 550 kg (depending on the model)

- Flexible mounting of point and wing options

- Low horsepower requirement due to curved deflector

- Optimum residue mixing even at shallow working depths

The TerraGrip tine system impresses due to its flexibility with regard to the various point and wing options. The low horsepower requirement and the excellent mixing behaviour are due to the curved shape and the low angle of the point.

Points

- MulchMix point

- MulchMix point HM

- MulchMix point HM Plus

- Point LD

- Point LD Plus

- Point ULD Plus

The point range covers all requirements for loosening and breaking compaction up to a working depth of 35 cm.

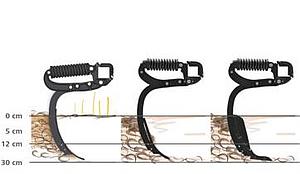

MulchMix without wing

Deep and intensively mixing tillage

- Deep loosening and intensive mixing of the soil

- Working depths: 15 to 30 cm

- Various carbide versions

The MulchMix point is used without wings if you want to work deeper than 15 cm and achieve an intensive mixing. Organic matter is mixed over the whole cultivation depth. The MulchMix points are available in different carbide versions to meet the most different requirements.

LD points

Primary soil cultivation, breaking compaction zones

- LD = Low Disturbance point

- 40 mm wide point for deep loosening without moving too much soil

- Working depth: 20 to 30 cm

The LD point can loosen deeply without mixing the soil too intensively. Due to its width of 40 mm, no large clods are not brought to the surface. The working depth ranges between 20 and 30 cm.

Additional Features

Fertiliser distributor

- Ideal for local fertilisation via the cultivator points

- The user can decide how to apply the fertiliser

- 100 % on the surface, 50 % at depth, 50 % on the surface or 100 % at depth

- Can be combined with the front tank Partner FT

The fertiliser distributor is ideal to apply fertiliser direct to where the plant needs it. The user can decide where he wants to apply the fertiliser – on the surface, at depth or both.

FertiProf Tiger 4 MT rigid

- Fitted directly on the Tiger

- Capacity of 2 800 l

- Integrated metering

- Single hopper system or double hopper system

The ideal combination to apply fertiliser with the Tiger. Depending on the customer requirements, with single hopper or double hopper and with a maximum capacity of 2 800 l.

Only for Tiger 4 MT rigid

Pronto TD as an additional equipment for the Tiger

- Seed drill that can be fitted on the Tiger

- Well-proven TurboDisc seed coulters

- Saves additional passes

- Optimal for sowing directly after tillage

With the Pronto TD, HORSCH offers a seed drill that can be fitted on the Tiger models – ideal for sowing the following crop directly after tillage. Thus, water can be saved efficiently, and ideal emergence is guaranteed.

TopRing packer with tyre packer

- Additional packer behind the tyre packer

- Hydraulically adjustable

- Cast iron packer elements guarantee a consolidation between the tyres

- All-over consolidation

The TopRing packer guarantees an even consolidation over the whole working width of the Tiger. If desired, it can be moved in or out hydraulically. On the headlands, the TopRing packer automatically moves upwards for more clearance.

Only in combination with tyre packers.