Express TD

driven by the soil

What are the excelling features of the Express TD?

The Express TD combines the advantages of a manoeuvrable 3-point mounted seed drill with the efficiency of a Pronto DC. The compact high speed drill with low horse power requirement guarantees a noticeable increase in productivity.

Preparation

The well-proven DiscSystem of the Express TD guarantees a perfect production of fine soil at an operational speed of 10 to 20 km/h. Due to the intensive tillage it can do without a pto-shaft. Due to the high clearance the 460 mm discs are very efficient even if there are high amounts of organic material. The working depth of the DiscSystem can be adjusted hydraulically and comfortably from the tractor.

Seedbed preparation

A very even emergence is the prerequisite for an even plant growth. To achieve this aim, the seedbed has to be levelled and consolidated in an optimum way. The packer elements of the FarmFlex packer with a diameter of 54 cm are especially coordinated with the seed coulters.

Express TD

Professional seed drill with 3-point linkage

- Safe emergence due to perfect embedding of the seed

- Optimum use of the ideal sowing times due to high hectare output and operational speeds up to 20 km/h

- Simpler, safer, faster – implemented consistently in the whole adjustment process

- Compact arrangement of the tools with 3-point linkage

TECHNICAL SPECIFICATIONS

| HORSCH Express | 3 TD | 3.5 TD |

| Working width (m) | 3.00 | 3.50 |

| Transport width (m) | 3.00 | 3.50 |

| Filling height (m) | 2.21 | 2.21 |

| Length without / Length with PE marker (m) | 3.67 / 4.00 | 3.67 / 4.00 |

| Weight (kg)* | 2 600 – 2 950 | 3 000 – 3 400 |

| Hopper capacity single hopper (l) | 1 500 | 1 500 |

| Dimension of feed opening (m) | 0.88 x 2.42 | 0.88 x 2.42 |

| Number of seed coulters | 20 | 24 |

| Coulter pressure seed coulters (kg) | 5 – 120 | 5 – 120 |

| Seed coulters / press wheels Ø (cm) | 34 / 32 | 34 / 32 |

| Row spacing (cm) | 15.00 | 14.50 |

| Packer Ø (cm) FarmFlex packer | 54 | 54 |

| Working speed (km/h) | 10 – 20 | 10 – 20 |

| Power demand (kW/hp) | 90 – 140 / 125 – 190 | 105 – 160 / 145 – 220 |

| DA control devices | 1 (+1 hydr. fan direct drive, +1 hydr. adjustment DiscSystem, +1 bout marker a. +1 hydr. coulter pressure adjustment) | |

| Depressurized return flow (max. 5 bar) | 1 (only with hydr. fan direct drive) | 1 (only with hydr. fan direct drive) |

| Oil quantity hydr. fan (l/min) | 20 – 25 | 20 – 25 |

| 3-point linkage | 3-point Cat. III | 3-point Cat. III |

* Weight of the empty machines with minimum / maximum equipment

| HORSCH Partner FT | Partner FT |

| Transport width (m) | 2.50 |

| Height (m) | 1.56 |

| Length without additional weights (m) | 1.44 |

| Weigth without additional weights (kg) | 700 |

| Hopper capacity (l) | 1 600 |

| Dimensions of feed openings (m) | 2.30 x 0.67 |

| Filling height (m) | 1.56 |

| DA control devices | 1 |

| Depressurized return flow (max. 5 bar) | 1 |

| Oil quantity hydr. fan (l/min) | 20 – 35 |

| Implement mounting tractor-side | 3-point Cat. II and III |

Features

DiscSystem – tyre packer

DiscSystem – perfect seedbed preparation in all conditions

- Effective crumbling and even levelling across entire operational width

- High clearance increases operational options and reliability

- Better performance at increased speed

- Hydraulic depth control, adjustable during operation (optional)

Efficient consolidation

- Targeted and homogeneous levelling and consolidation in front of every seed coulter

- Profiled packer for efficient consolidation below the seed horizon guides the water safely to the grain and thus guarantees optimum emergence

- Compact design of the packer (ø 54 cm) while at the same time the load-bearing capacity on light, sandy soils is still high

- Standard carbide scraper guarantee safe working in wet, cohesive conditions

TurboDisc

TurboDisc – the third generation guarantees an advance in seed placement

A perfect placement of the seed and an immediate seed-soil contact are the prerequisites for a safe and regular emergence. HORSCH perfectly meets the challenge to achieve this aim even at high operational speeds. The solution is called TurboDisc. The DoubleDisc seed coulter that HORSCH has been using and developing further for more than 20 years convinces by its precise seed placement. The press-wheel-controlled coulter design allows a quick adaption to the soil at high speeds. This is the only way to keep up the placement depth for every single grain of seed.

The DoubleDisc seed coulter with maintenance-free bearing opens the soil and thus allows for an undisturbed seed placement. The integrated uniformer guarantees a fixing of the seed at the bottom

of the seed furrow even at high operational speeds. A carbide coated scraper keeps the area between the discs clean and prevents blocking even in cohesive and wet conditions. The 5- or 7.5-cm-wide press wheel guarantees optimum seed-soil contact and an exact depth control.

In addition to the excellent adaption to the soil the TurboDisc seed bar impresses by its easy handling: coulter pressure and sowing depth do not influence each other when being adjusted. The maintenance-free rubber bearing of the seed coulters transfers a coulter pressure of 120 kg and thus guarantees a smooth coulter – at an operational speed of up to 20 km/h. Moreover, the rubber bearing acts as an overload protection and shock absorber for stones.

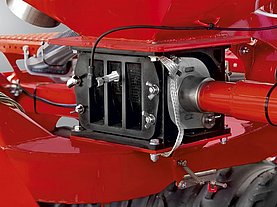

Metering unit – Electric drive for metering the seed. Allows for a quick, simple and precise calibration.

Emptying hopper device

Tramline system

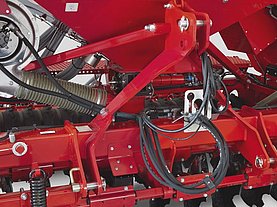

Depth adjustment DiscSystem via two adjusters. Optional: can be made while driving via two hydraulic cylinders.

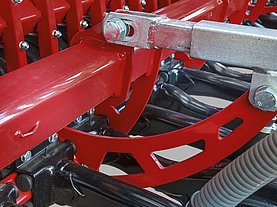

Full width FarmFlex packer – resistant to stones

Hydraulic depth adjustment DiscSystem (optional)

Maintenance-free oil bath bearing

High service life with low wear

Spring-loaded track-eradicator tines (optional)

3-point linkage Cat. III

Radar sensor for an exact recording of the speed and to control the seed quantity

Lighting

for safe road transport

Storage box – lockable and sealed

Pre-emergence marker (optional)

Blockage monitoring sensors

for seed and fertiliser

Continuous coulter pressure adjustment

Manual adjustment increases the pre-stressing of the rubber elements

2-row DiscSystem – Considerably lower horsepower requirement compared to powered front tools (e. g. power harrow). Excellent seedbed preparation at high working speeds.