The Leeb LT:

Engineering for professionals

The basis

- Solidly designed frame made of quality steel

- Optional: air-suspended axle with level compensation

- Solid drawbar connection for large clearance, top or bottom connection, depending on the vertical load

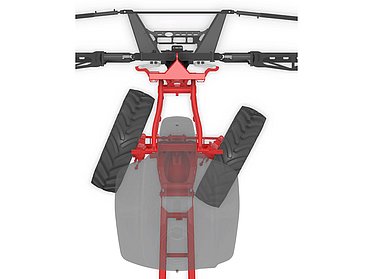

Steering axle – less tramline damage (optional)

- Steering axle for stable positioning of the boom with high stability and exact tracking to avoid tramline damage

- Optimal, even in uneven terrain

- Large steering angle due to a taper-cut frame design

Large tyres – less ground pressure

- Wheels with diameter of up to 2.05 m

- Maximum ground contact area with perfectly adapted air pressure

- Adapted Tyre Pressure Control – automatic tyre pressure regulation that is completely integrated in the software

Extremely low centre of gravity

- Tank shape is optimised with regard to the surging force

Taking care of the crop

- Smooth machine underbody

- No edges and corners on the underside of the machine

- Hydraulically foldable and fully covered support leg

Modern plastic tank

- Conical geometries for low surge forces

- 500 litre fresh water tank: enough water for a complete inside cleaning as only very little residual quantities remain in the system.

- Large radii, absolutely smooth surfaces and no back tapers for easy cleaning.

- Deep sump area for complete discharge and minimum residual quantities even on slopes.

Three equipment versions

Eco

- Manual operation for the suction and pressure side

- Piston diaphragm pump (400 l/min) driven by pto-shaft

- Hydraulic agitator

CCS

- Manual operation for the suction and pressure side

- Additional piston diaphragm pump for the continuous inside cleaning system CCS

- Continuous inside cleaning can be operated in the cabin

- Oil-driven (Load Sensing) centrifugal pump (600 l/min)

- Hydraulic agitator

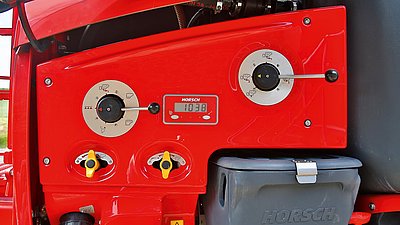

CCS Pro

- Electronic operation on pressure and suction side for complete control from the cabin

- Additional piston diaphragm pump for the continuous inside cleaning system CCS with automatic washing programs, e. g. intensive washing program, boom rinsing

- Centrifugal pump driven via oil (Load Sensing) (600 l/min)

- External control terminal

- Hydraulic agitator, is controlled electronically via terminal and external control unit. Automatic switch-off if the residual quantity in the mixture tank falls below 150 liter.

Leeb LT details

- Tank capacity: 4 000, 5 000 and 6 000 litre

- Top or bottom linkage selectable

- Low gravity centre of the spraying tank

- Tank made of polyethylene (PE)

- Optimised tank shape for transport and cleaning

- Optimised hose laying reduces hose lengths to a minimum

- Boom suspension is designed as a parallelogram – hydr. spring-loaded and damped.

- Soft and smooth boom rest even in hilly terrain and at high operational speeds.

- The geometry of the parallelogram has been designed in such a way that the boom is kept close to the axle. The suspension is extremely torsion-resistant and thus perfectly suitable for the automatic boom controlsystem Leeb BoomControl.

- Nozzle protection against mechanical damage of the nozzles and wind protection during the development of the spraying fan

Strong, convincing arguments

- Less drift and high working speeds due to automatic BoomControl due to low target area distance

- High working speeds due to hydro-pneumatic boom damping

- Complete circulation in stainless steel circulatoin tubes to the nozzle

- Continuous ground clearance

- Crop protecting, smooth underfloor design

- Large tyres up to ø 2.05 m possible

- Gravity-optimised and waisted frame design for large steering angles

- Novel operating concept

- Central arrangement of control units

- Pumping capacity up to 600 l/min

- Efficient induction hopper made of PE

- Compact external dimensions in transport position

- No parts protruding towards the tractor

- Continuous inside cleaning (CCS and CCS Pro)

- Spring-loaded axle

- Integrated overload protection in the boom

Option

- Fully integrated axle steering (when reversing automatic centring of the steering axle)

- Induction hopper made of stainless steel

- NightLight: powerful LED spraying cone lighting with washing device

- Pre-field lighting: 2 LED headlights

- Lighting in the working range of the induction hopper

- SectionControl (automatic section control)

- Pneumatic spring-loaded axle

- Hose drum or high-pressure cleaner for outside cleaning

- BoomControl expansion with 2 sensors

- Camera system for the area behind the machine

- Spacious container deposit facility below the right side cover

- Individual section layout according to the customer’s requirements

- Second pressure filter in the rear of the parallelogram ATP Control for automatic regulation of the tyre pressure

- AutoSelect, automatic switching between the nozzle levels

- Connect & Fold system to integrate underleaf spraying systems

TECHNICAL SPECIFICATIONS

| HORSCH Leeb LT Light | 4 LT Light | 5 LT Light |

| Measures and weights | ||

| Unladen weight (kg) | 4 150 – 5 050 | 4 150 – 5 050 |

| Tongue load empty (kg) | 450 – 750 | 450 – 750 |

| Max. permissible vertical load (kg) | 2 500 | 2 500 |

| Axle load empty (kg) | 3 700 – 4 300 | 3 700 – 4 300 |

| Max. permissible axle load (kg) | 8 250 | 8 250 |

| Overall length max. (transport position) (m) | 7.70 | 7.70 |

| Transport width (transport position) (m) | 2.55 | 2.55 |

| Transport height (m) | 3.40 – 3.60 | 3.40 – 3.60 |

| Track widths (m) | 1.80 / 2.00 / 2.25 | 1.80 / 2.00 / 2.25 |

| Ground clearance axle (m) | 0.75 | 0.75 |

| Tank | ||

| Mixture tank nominal capacity (l) | 4 000 | 5 000 |

| Mixture tank actual capacity (l) | 4 400 | 5 300 |

| Fresh water tank (l) | 500 | 500 |

| Hand wash tank (l) | 15 | 15 |

| Spraying boom | ||

| Working widths | 18 / 12 5 sect. | 18 / 12 5 sect. |

| 21 / 12 5 sect. | 21 / 12 5 sect. | |

| 24 / 12 5 sect. | 24 / 12 5 sect. | |

| 27 / 21 / 12 7 sect. | 27 / 21 / 12 7 sect. | |

| 28 / 21 / 12 7 sect. | 28 / 21 / 12 7 sect. | |

| 30 / 21 / 12 7 sect. | 30 / 21 / 12 7 sect. | |

| Sections, min. / max. (pieces) | 6 – 42 | 6 – 42 |

| Working height (m) | 0.3 – 2.5* | 0.3 – 2.5* |

| Pump output CCS and CCS Pro (l/min) | 600 | 600 |

| Max. discharge at the boom (l/min) | 350** | 350** |

| Pump output (l/min) | 400 | 400 |

| Max. discharge at the boom (l/min) | 320** | 320** |

| Working pressure, max. (bar) | 8 | 8 |

| Working speed (km/h) | 4 – 20 | 4 – 20 |

* Working height depends on the height of the coupling point of the tractor and the tyres

** The indicated application rates apply to water with a spraying pressure of approx. 5 bar. With other pressures the application rates may differ upward and downward.

| HORSCH Leeb LT | 4 LT | 5 LT | 6 LT |

| Measures and weights | |||

| Unladen weight (kg) | 4 250 – 6 400 | 4 250 – 6 400 | 4 250 – 6 400 |

| Tongue load empty (kg) | 450 – 800 | 450 – 800 | 450 – 800 |

| Max. permissible vertical load (kg) | 3 000 | 3 000 | 3 000 |

| Axle load empty (kg) | 3 800 – 5 600 | 3 800 – 5 600 | 3 800 – 5 600 |

| Max. permissible axle load (kg) | 10 000 | 10 000 | 10 000 |

| Overall length max. (transport position) (m) | 7.70 | 7.70 | 7.70 |

| Transport width (transport position) (m) | 2.55 | 2.55 | 2.55 |

| Transport height (m) | 3.40 – 3.60 | 3.40 – 3.60 | 3.40 – 3.60 |

| Track widths (m) | 1.80 / 2.00 / 2.25 | 1.80 / 2.00 / 2.25 | 2.00 / 2.25 |

| Ground clearance axle (m) | 0.85 | 0.85 | 0.85 |

| Tank | |||

| Mixture tank nominal capacity (l) | 4 000 | 5 000 | 6 000 |

| Mixture tank actual capacity (l) | 4 400 | 5 300 | 6 400 |

| Fresh water tank (l) | 500 | 500 | 500 |

| Hand wash tank (l) | 15 | 15 | 15 |

| Spraying boom | |||

| Working widths | 18 / 12 5 sect. | 18 / 12 5 sect. | 18 / 12 5 sect. |

| 21 / 12 5 sect. | 21 / 12 5 sect. | 21 / 12 5 sect. | |

| 24 / 12 5 sect. | 24 / 12 5 sect. | 24 / 12 5 sect. | |

| 27 / 21 / 12 7 sect. | 27 / 21 / 12 7 sect. | 27 / 21 / 12 7 sect. | |

| 28 / 21 / 12 7 sect. | 28 / 21 / 12 7 sect. | 28 / 21 / 12 7 sect. | |

| 30 / 21 / 12 7 sect. | 30 / 21 / 12 7 sect. | 30 / 21 / 12 7 sect. | |

| 30 / 24 / (12) 7 sect. | 30 / 24 / (12) 7 sect. | 30 / 21 / (12) 7 sect. | |

| 32 / 24 / (12) 7 sect. | 32 / 24 / (12) 7 sect. | 32 / 24 / (12) 7 sect. | |

| 33 / 24 / (12) 7 sect. | 33 / 24 / (12) 7 sect. | 33 / 24 / (12) 7 sect. | |

| 36 / 24 / (12) 7 sect. | 36 / 24 / (12) 7 sect. | 36 / 24 / (12) 7 sect. | |

| 38 / 27 / (14) 7 sect. | 38 / 27 / (14) 7 sect. | 38 / 27 / (14) 7 sect. | |

| 39 / 27 / (14) 7 sect. | 39 / 27 / (14) 7 sect. | 39 / 27 / (14) 7 sect. | |

| 40 / 27 / (14) 7 sect. | 40 / 27 / (14) 7 sect. | 40 / 27 / (14) 7 sect. | |

| 40 / 28 / (14) 7 sect. | 40 / 28 / (14) 7 sect. | 40 / 28 / (14) 7 sect. | |

| 42 / 28 / (14) 7 sect. | 42 / 28 / (14) 7 sect. | 42 / 28 / (14) 7 sect. | |

| 44 / 30 / (14) 7 sect. | 44 / 30 / (14) 7 sect. | 44 / 30 / (14) 7 sect. | |

| 45 / 30 / (14) 7 sect. | 45 / 30 / (14) 7 sect. | 45 / 30 / (14) 7 sect. | |

| Sections, min. / max. (pieces) | 6 – 42 | 6 – 42 | 6 – 42 |

| Working height (m) | 0.3 – 2.5* | 0.3 – 2.5* | 0.3 – 2.5* |

| Pump output CCS and CCS Pro (l/min) | 600 | 600 | 600 |

| Max. discharge at the boom for CCS and CCS Pro (l/min) | 350** | 350** | 350** |

| Pump output Basic (l/min) | 400 | 400 | 400 |

| Max. discharge at the boom for Basic (l/min) | 300** | 300** | 300** |

| Working pressure, max. (bar) | 8 | 8 | 8 |

| Working speed (km/h) | 4 – 20 | 4 – 20 | 4 – 20 |

* Working height depends on the height of the coupling point of the tractor and the tyres

** The indicated application rates apply to water with a spraying pressure of approx. 5 bar. With other pressures the application rates may differ upward and downward.

Indications may vary depending on the equipment.