Pronto NT

Seedbed preparation in strips

Which requirements does the seed drill have to meet?

- Precise seed placement – as even germination increases yield potential.

- High seeding speed – as perfect timing is essential.

- Tolerance for seedbed conditions – as flexibility saves money.

How does the Pronto achieve such even germination?

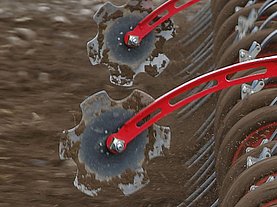

- Wavy discs pre-cut the seed row in a targeted way and remove harvest residues, rough structures or dry soil from the immediate seed area

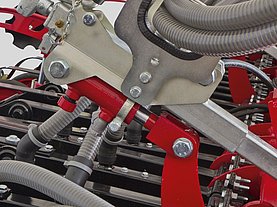

- The mounting of the TurboDisc coulters allows for vertical adjustment movement of up to 15 cm and ensures precise contour following. All seeds are placed exactly at the specified depth.

- 4 rubber elements/coulters release a pressure of up to 120 kg, sufficient to reliably keep them in the ground at high speed.

- The rubber wheel at the coulter-end ensures precise seed depth and proper seed-to-soil contact.

Faster

- High output – due to working speeds of 10 – 20 km/h

- Short turning times – due to compact design

- Low idle times – due to large seed and fertiliser hoppers

Simpler

- Short set-up times – due to uncomplicated connection to the tractor

- Quickly ready for action – due to easy adjustment of seed quantity, seed depth and coulter pressure

- Unproblematic changing of the seed

- Low maintenance requirements

Safer

- TurboDisc seed coulter – precise seed placement at high working speeds

- TurboDisc coulters are individually controlled by press wheels and are equipped with integrated shock absorbers

- Exact adaption to uneven soils up to a difference of 15 cm

- Stepless coulter pressure adjustment 5 – 120 kg per TurboDisc coulter

Pronto NT

Precise in every terrain

- High efficiency as a result of the operational speeds of up to 20 km/h and the optimised hopper concept

- Safe emergence due to the well-proven Pronto technology

- High service life and reliability – lowest costs for seeding

- Specialised for spring seeding and for sowing in wet conditions – sowing without a packer allows for sowing in very wet conditions

- Targeted seed strip preparation with wavy discs (removing, crumbling and consolidation)

- Fertilisation to the point – PPF (Pronto 10 / 12 NT) and G & F fertilisation systems

Pronto 6 / 8 / 9 NT

With the well-proven TurboDisc coulter and the compact design without a seed wagon the Pronto 6 / 8 / 9 NT is suitable for mulch and direct seed. Operational speeds up to 20 km/h allow for a high area output even for smaller working widths. The wavy cutting discs cut organic material and cultivate the soil only in the seed rows. Thus, the horsepower requirement is very low.

The large seed hopper (4 000 l) guarantees low idle times and even without additional weights allows for a sufficient pressure of the cutting discs. This pressure is transferred via the sophisticated hydraulic system of the machine. If necessary, additional weights up to 1 400 kg can be mounted at the frame. Due to flexible frame sections the soil adaption of the seed unit is excellent.

The double hopper version (5 000 l) allows for applying seed and fertiliser at the same time. In addition, a micro-granular unit is available to apply another component. The micro-granular unit can be combined with double hopper as well as with the single hopper version. Thus, up to three components (seed, fertiliser, micro-granular compounds) can be metered in only one pass.

Filling auger double hopper output 500 kg/min

Hydraulically foldable in transport position

Large chassis tyres

Even germination is the basis for high yields

Double hopper

Tramline valve

Pronto 10 / 12 NT

The Pronto NT is a compact universal seed drill with the Pronto system (cultivating, sowing and pressing) for mulch or no-till farming. Especially in no-till conditions the tool combination of ondulated coulter / cutting disc and the well-proven TurboDisc coulter has important advantages. Only that area of the soil is cultivated where then the seed will be placed.

The HORSCH TurboDisc coulters efficiently adjust to uneven soils, guarantee high coulter pressure and a precise seed placement. There are two different types of PPF system available to spread fertiliser. The fertiliser can either be placed together with the seed by the TurboDisc coulters or between the seed rows by fertiliser discs the depth of which can be adjusted separately (optional equipment).

The direct connection of seed waggon and seed unit results in a high coulter pressure at the cutting discs and the fertiliser coulter without using any additional ballast weight.

Concept of the machine

- Top-efficiency for large farms

- Optimised for no-till farming

- Low power demand – the soil is only cultivated in that area where the seed will be placed

- Lower power demand due to ondulated coulters / cutting discs as previous tools – PPF fertiliser system is available as an option (fertiliser is placed together with the seed by the TurboDisc coulters or between the seed rows by fertiliser discs the depth of which can be adjusted separately)

- TurboDisc seed coulters for precise seed placement

- Seed waggon with a capacity of 12 000 l (partition 50 : 50 seed / fertiliser)

- Manoeuvrable machine due to compact design

- Low power demand due to low dead weight

TECHNICAL SPECIFICATIONS

| HORSCH Pronto NT | 6 NT | 8 NT | 9 NT |

| Working width (m) | 6.00 | 8.00 | 8.80 |

| Transport width (m) | 3.50 (option 2.95) | 3.50 (option 2.95) | 3.50 (option 2.95) |

| Transport height without / with bout marker (m) | 3.25 | 3.53 / 3.60 | 3.96 / 4.40 |

| Length short / long tongue (m) | 6.96 / 7.78 | 6.96 / 7.78 | 6.96 / 7.78 |

| Axle load (kg)* | 4 400 – 5 150 | 5 000 – 5 700 | 5 200 – 6 000 |

| Vertical load (kg)* | 2 600 – 2 850 | 2 700 – 3 300 | 3 000 – 3 500 |

| Hopper capacity single hopper (l) | 4 000 | 4 000 | 4 000 |

| Capacity double hopper (I) | 5 000 (40 : 60) | 5 000 (40 : 60) | 5 000 (40 : 60) |

| Feed opening single hopper (m) | 1.00 x 2.40 | 1.00 x 2.40 | 1.00 x 2.40 |

| Feed opening double hopper (m) | per 0.99 x 0.72 | per 0.99 x 0.72 | per 0.99 x 0.72 |

| Filling height single hopper (m) | 2.88 | 2.88 | 2.88 |

| Filling height double hopper (m) | 2.95 | 2.95 | 2.95 |

| Number of seed coulters | 30 | 40 | 44 |

| Coulter pressure seed coulters (kg) | 5 – 120 | 5 – 120 | 5 – 120 |

| Seed coulters / press wheels Ø (cm) | 34 / 32 | 34 / 32 | 34 / 32 |

| Row spacing seed coulters (cm) | 20.00 | 20.00 | 20.45 |

| Cutting disc system Ø (cm/inch) | 46 / 18 | 46 / 18 | 46 / 18 |

| Tyre size chassis | 600 / 55 – 26.5 | 600 / 55 – 26.5 | 600 / 55 – 26.5 |

| Tyre size support wheels | 10.0 / 75 – 15.3 | 10.0 / 75 – 15.3 | 10.0 / 75 – 15.3 |

| Working speed (km/h) | 10 – 20 | 10 – 20 | 10 – 20 |

| Power demand (kW/hp) | 120 – 185 / 160 – 250 | 155 – 215 / 210 – 290 | 175 – 240 / 240 – 330 |

| Double-acting control devices | 2 | 2 | 2 |

| Depressurized return flow (max. 5 bar) | 1 | 1 | 1 |

| Oil quantity hydr. fan (l/min) | 35 – 45 | 35 – 45 | 35 – 45 |

| Lower link linkage | Cat. III a. III / IV | Cat. III a. III / IV | Cat. III a. III / IV |

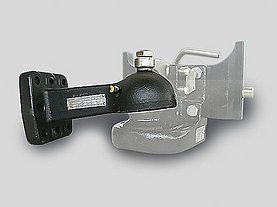

| Adj. draw linkage | Hitch Ø 46 – 58 mm | Hitch Ø 46 – 58 mm | Hitch Ø 46 – 58 mm |

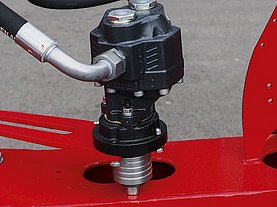

| Ball-type linkage | K 80 | K 80 | K 80 |

* Weight of the machines unloaded with minimum / maximum equipment

| HORSCH Pronto NT | 10 NT | 12 NT |

| Working width (m) | 10.40 | 12.00 |

| Transport width (m) | 4.30 | 4.30 |

| Transport height (m) | 4.05 / 4.34 with bout marker | 4.95 / 5.20 with bout marker |

| Length cpl. without / with PPF system (m) | 11.40 / 12.00 | 11.20 / 11.80 |

| Weight without / with SW 12 000 SD (kg)* | 9 680 / 13 150 | 10 370 / 13 840 |

| Capacity double hopper (I) | 12 000 (50 : 50) | 12 000 (50 : 50) |

| Feed opening double hopper (m) | per 0.99 x 0.72 | per 0.99 x 0.72 |

| Filling height double hopper (m) | 3.40 | 3.40 |

| Number of PPF coulters | 26 | 30 |

| Coulter pressure PPF coulters (kg) | up to max. 250 | up to max. 250 |

| Number of seed coulters | 52 | 60 |

| Coulter pressure seed coulters (kg) | 5 – 120 | 5 – 120 |

| Seed coulters / press wheels Ø (cm) | 34 / 32 | 34 / 32 |

| Row spacing seed coulters / PPF coulters (cm) | 20 / 40 | 20 / 40 |

| Cutting disc system Ø (cm/inch) | 46 / 18 | 46 / 18 |

| Tyre size SW | 650 / 65 R 38 (optional 900 / 60 R 32 or twin tyres 20.8 R 42) | |

| Tyre size rear chassis | 400 / 60 – 15.5 | 400 / 60 – 15.5 |

| Working speed (km/h) | 10 – 20 | 10 – 20 |

| Power demand (kW/hp) | 191 – 208 / 260 – 310 | 205 – 240 / 280 – 330 |

| Double-acting control devices | 2 | 2 |

| Depressurized return flow (max. 5 bar) | 1 | 1 |

| Oil quantity hydr. fan (l/min) | 90 | 90 |

| Adj. draw linkage | Bolt Ø 50 – 55 a. 60 – 70 mm | Bolt Ø 50 – 55 a. 60 – 70 mm |

| Ball-type linkage | K 80 | K 80 |

* Weights of the machines in minimum equipment

Features

Single hopper

Hydraulic filling auger

Radar sensor

Tank discharge opening

Tool box

Robust control sensors

Tramline system

Smooth, precise metering rotors

Precision harrow

Marker

Hydraulic fan with pto-shaft drive

Additional weights

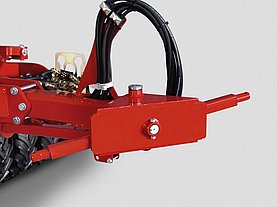

Draw linkage

2-point linkeage

Ball head coupling

Pre-emergence marker

Hydraulic coulter pressure adjustment is available as an option

Stop slide Pronto single hopper version

Hydaulic fan

PTO driven pump

Simple calibration

Quick and precise calibration