The HORSCH Joker CT is a compact disc harrow that is ideal for stubble cultivation, the incorporation of catch crops, seedbed preparation or the incorporation of organic fertiliser.

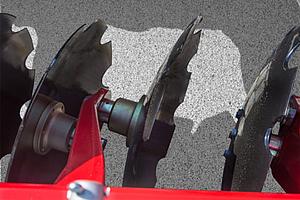

Compact disc harrow with high clearance as two discs are fitted on one arm with rubber torsion suspension

- Produces a high amount of fine soil in the germination horizon

- Efficient consolidation in the germination horizon

- Reduced problems in case of long harvest residues and shallow cultivation

- High clearance as the disc elements are arranged in pairs

- Optimum penetration due to aggressively serrated annular plates and high machine weight

The Joker CT line stands for intensive mixing during shallow tillage or stubble cultivation. Due to the robust design with working widths from 3 to 7 m, the Joker CT is the optimum machine for 3-point linkage – whether it is used for the linkage to a tractor or for the incorporation of liquid manure in combination with liquid manures tanks or self-propelled vehicles. The Joker can also be equipped with our well-known MiniDrill to simultaneously sow catch or cover crops. Depending on the conditions, different packer options can be mounted.

TECHNICAL SPECIFICATIONS

| HORSCH Joker CT | 3 CT | 4 CT | 5 CT | 6 CT | 7 CT |

| Working width (m) | 3,00 | 4,00 | 5,00 | 6,00 | 7,00 |

| Transport width (m) | 3,00 | 2,95 | 2,95 | 2,95 | 2,95 |

| Transport height (m) | 1,90 | 2,80 | 3,25 | 3,70 | 4,00 |

| Length (m) | 2,50 | 2,90 | 2,90 | 2,90 | 2,90 |

| Length incl. Mono TG (m) | 3,70 | --- | --- | --- | --- |

| Weight (kg) | 1600 - 2600 | 2400 - 3100 | 2800 - 3500 | 3000 - 3900 | 3500 - 4550 |

| Weight incl. Mono TG (kg) | 2300 - 2600 | --- | --- | --- | --- |

| DiscSystem discs Ø (cm) | 52 | 52 | 52 | 52 | 52 |

| DiscSystem disc thickness (mm) | 6 | 6 | 6 | 6 | 6 |

| Number of DiscSystem discs (Piece) | 24 | 32 | 40 | 48 | 56 |

| Cutting angle DiscSystem discs (°) | 17 | 17 | 17 | 17 | 17 |

| DA control devices | 0 (+1 with hydr. depth adjustment) | 1 (+1 with hydr. depth adjustment) | 1 (+1 with hydr. depth adjustment) | 1 (+1 with hydr. depth adjustment) | 1 (+1 with hydr. depth adjustment) |

| Horsepower requirement (kW/hp) | 65 – 90 / 90 – 120 | 90 – 120 / 120 – 160 | 110 – 150 / 150 – 200 | 130 – 175 / 180 – 240 | 205 – 260 / 280 – 350 |

| Horsepower requirement incl. Mono TG (kW/hp) | 140 / 190 | --- | --- | --- | --- |

| Number of tines Mono TG (Piece) | 5 | --- | --- | --- | --- |

| Tine spacing Mono TG (cm) | 60 | --- | --- | --- | --- |

| Implement attachment 3-point linkage Joker CT | 3-point Cat. II/III | 3-point Cat. III/IV | 3-point Cat. III/IV | 3-point Cat. III/IV | 3-point Cat. III/IV |

| Implement attachment 3-point linkage Mono TG | 3-point Cat. III | --- | --- | --- | --- |

Features

Disc serrated Ø 52 cm

- Disc serrated Ø 52 cm

- Excellent penetration of the soil

- Intensive mixing

- Different hardness grades in one disc

The serrated disc with a diameter of 52 cm can be used in different situations. For working depths up to 15 cm, it reliably penetrates the soil. The serrated cutaways allow for an excellent incorporation of high amounts of straw. The serrated profile almost completely prevents the discs from stopping even in very light soils. Small disc diameter for high rotational speeds and a high production of fine soil.

CoverCrush disc Ø 52 cm

- Working depths up to 8 cm

- Good production of fine soil

- Crushing of cover or catch crops

The CoverCrush disc is ideal for a shallow use up to 8 cm. Due to the large contact area, a lot of material is crushed but is only mixed in to a limited extent.

RollFlex packer

- Deep consolidation with loose soil surface

- High levelling capacity due to intermediate levelling tine

- Self-cleaning, without scrapers

- High operational reliability

The RollFlex packer guarantees high reliability on changing soil types even in wet conditions. Due to the deep consolidation, excessively loose soil is compacted, clods are crushed. The result is an optimum environment with the optimum drying conditions.

RollPack packer

- Steel ring roller with a diameter of 55 cm

- Deep strip consolidation

- Flexible conditions of use

- Weight per m working width: 125 kg

The RollPack packer is ideal for light and medium sites. Due to the good consolidation and the rigid ring elements the range of use is very wide.

Additional Features

Harrow rear 1-row

- Combs out weeds and removes soil from the roots

- Places organic material loosely on the surface

- Additional levelling effect

The 1-row harrow reliably combs out weeds and places them loosely on the cultivated horizon. They then dry out and die off. The harrow guarantees an excellent levelling and provides an additional amount of fine soil on the surface.

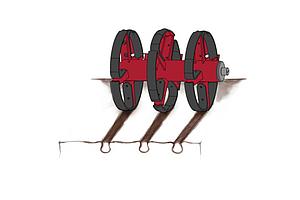

Preparation kit for liquid manure mounting

- Distributor holder for Vogelsang ExaCut or Bomech Alrena exact distributor

- Liquid manure exits through a diameter of 50 mm outlet

- Available for Joker 4/5/6 and 7 CT as well as Joker 5/6 and 8 HD

Due to the liquid manure distribution mounting kit which is an option ex factory, the Joker CT and Joker HD are also ideal for incorporating liquid fertiliser. In this case, the packer can be replaced by a harrow. Depth control is then carried out by the front support wheels.