Managing Wet Seeding Conditions

Average reading time: 4 minutes

Once again, farmers across the US are battling cool, wet spring conditions. As the extended forecast raises the possibility of a continued wet forecast, the realization of a 24-hour planting window becomes more of a reality. This has been a recurring theme in parts of the Corn Belt for the Spring of 2022. The use of high-speed planters, with large carrying capacities, has been a blessing for many.

When managing these difficult and challenging conditions, it is of the upmost importance to have the correct seed technology, make sound management decisions, and utilize equipment to its full potential.

Why do these factors have such a large impact on the entire growing season?

Many costly mistakes can be lessened or prevented with the right knowledge and equipment. Mistakes made at planting follow the crop through the entire season. Some negative impacts of planting in wet conditions include nutrient deficiencies, increase of soil borne diseases, sidewall smear and compaction, field compaction and soil build-up on ground contact components.

Seed Technology has been one of the highest contributors in insuring a successful germination in such difficult conditions. From the vigor and tolerances selected and bred into these newer cultivars, to the elaborate seed treatments allowing seed to withstand cold, wet soils for a considerable amount of time. Seed technology has greatly improved compared to only a few decades ago. Why are farmers planting earlier than in the past? I believe this answer is simple: because they can, because a larger number of acres need to be covered, and certain crops have showed a large yield benefit. The risk involved is fractional compared to potential lost yield due to untimely planting.

Possibly the most difficult issue in cool, wet soils is compaction. The impact in wet soils is far greater than dry soils, depending on the soil type, because moisture acts as a lubricant between soil particles. This decreases soil porosity. Pore spaces are necessary for root growth by allowing exchange of air, water and nutrients. How can this inevitable issue be managed?

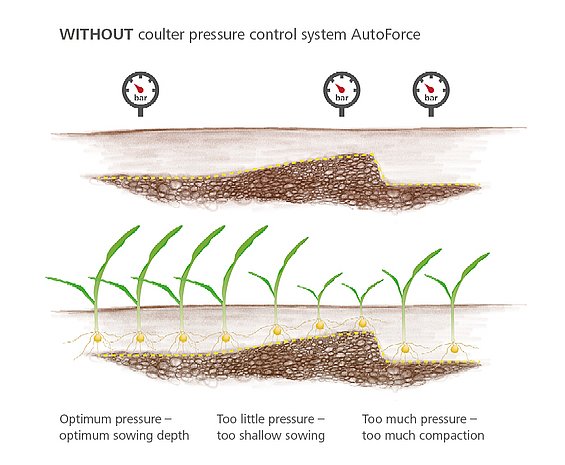

There are many different areas of compaction as a tractor and implements travel across a field. One area of compaction that can be manipulated is sidewall compaction with the planter. This is caused by too much downforce on either side of the seed furrow. The goal is to always maintain proper seed to soil contact. Having the row unit engaged, through downforce and weight transfer, using a firming device in-furrow, and utilizing the proper closing wheels.

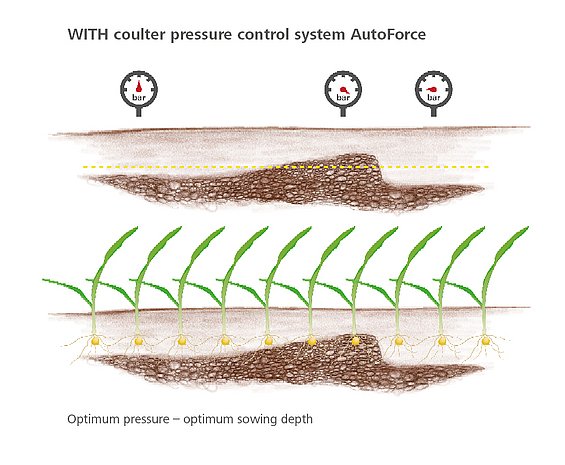

Row crop planters today can change this hydraulic downforce automatically. The load cell, located between the gauge wheel arms and the depth stop, converts resistance to applied pressure insuring proper seed placement and not over application. Horsch’s AutoForce system is designed to automatically adjust down pressure according to variances in field conditions to maintain a target gauge wheel pressure set by the operator.

For example, if a target gauge wheel pressure of 100lbs is set by the operator, the system will maintain this resistance from the ground. In harder soils the AutoForce will apply more downforce to achieve seeding depth/contact as the surface area of the opening discs travel through the soil. In conditions where there is adequate moisture, or looser soils, more downforce is not needed due to ease of penetration. For more details about AutoForce:

Sidewall compaction, from the gauge wheels, deters perpendicular root growth with the furrow; creating what many call “Tomahawk Roots”. Root interception, mass flow and diffusion of nutrients to the roots are now only occurring within the row instead of utilizing the entire surrounding area. Below is a picture posted on 1/7/22 of a) normal root growth and b) over applied downforce by Dan Quinn, Ph.D. Assistant Professor of Agronomy at Purdue University.

https://thekernel.info/sidewall-compaction/

Email: djquinn@purdue.edu

As always, physically check the downforce when changing conditions, or soil types, are encountered. I personally do this by barely being able to turn the gauge wheel with two hands. There is no pre-set available to accommodate every soil type, moisture level, present biomass, or planting depth. For more information on seeding techniques please visit, or call, the Horsch AgVision Farm.

Additional knowledge about compaction can be found in Horsch’s three-part series: Soil conservation vs. heavy machines