Avatar

A NEW CHAPTER IN NO-TILL FARMING

HORSCH have never lost sight of the products that for 30 years have been forming its reputation: the first Seed-Exactors left a permanent impression. If you go back to the beginning of the company, Michael Horsch at that time built a machine that was suitable for no-till farming.

The arguments at that time: disturb the soil as little as possible, encourage biodiversity and, of course, in the context of decreasing prices, save costs. Due to the opening of the eastern markets in the Nineties there suddenly was a large market for no-till farming equipment. However the pto-shaft driven technology could not be used for the large fields in the East.

With the experiences from the no-till sector Michael Horsch developed tine-based no-till technology for the eastern markets that is successfully sold there today. In the recent past, HORSCH thought about developing no-till technology based on disc coulters. It is not just suitable for the Latin American markets to disturb the soil as little as possible.

But also in other regions, too, the single disc coulter technology is of great interest – especially in Europe with increasing requirements in the sector of catch crops sowing to the sowing of main crops in catch crops or in regions that are faced with resistant weeds. In parts of Great Britain, Germany and France the farmers depend on new sowing technologies with reduced soil movement – a clear task for the Avatar.

The disc coulter technology plays an important role in large parts of Russia, Kazakhstan and China.

Good reasons for HORSCH to design our own Avatar line.

Avatar SW

INNOVATIVE, EFFICIENT, WELL-PROVEN COMPONENTS

Concept of the machine

- Maximum efficiency for large farms:

- Working width 12 m

- Seed waggon technology from the well-proven Pronto line

- Designed for highest requirements and maximum efficiency during the season

- Seed waggon

- Capacity of 12 000 litre for maximum efficiency

- Hoppers 50 : 50 seed / seed or seed / fertiliser (application as G & F version, seed and fertiliser in one row)

- Low horsepower requirement due to reduced soil movement

- Manoeuvrable machine due to compact design

- Low horsepower requirement due to low machine weight

12 metre working width

Capacity of 12 000 litre with a 50 : 50 split hoppers

Solid monitoring sensors for seed and fertiliser

Compact design

2-bar coulter design for maximum clearance

Avatar SW on the road

Avatar SW

Versatile, solid, precise

Versatile

- Can be used universally from direct drilling to cultivated soils

- Metering of up to three individual components

Robust

- High coulter pressure of up to 350 kg per individual row

- Stable and maintenance-free bearings for maximum service life

Precise

- Depth control at the individual coulter

- Closing wheels can be adjusted in an optimum way for the most different site conditions

TECHNICAL SPECIFICATIONS

| HORSCH Avatar | 12 SW |

| Working width (m) | 12.00 |

| Transport width (m) | 4.36 |

| Transport height (m) | 5.28 |

| Length (m) | 11.65 |

| Weight (kg)* | 19 160 |

| Seed hopper capacity double hopper (l) | 12 000 (50 : 50, per 6 000 l) |

| Feed opening double hopper (m) | per 0.99 x 0.72 |

| Filling height double hopper (m) | 3.34 |

| Number of seed coulters | 60 |

| Coulter pressure seed coulters (kg) | 350 |

| Seed coulter Ø (cm) | 48 |

| Closing wheels Ø (cm) | 33 |

| Depth control wheels Ø (cm) | 40 |

| Row spacing (cm) | 20 |

| Tyre size seed waggon | 650 / 65 R 38 |

| Tyre size seed unit | 400 / 60 – 15.5 |

| Working speed (km/h) | 6 – 15 |

| Power demand (kW/hp) from | 205 / 280 |

| DA control devices | 3 |

| Depressurized return flow (max. 5 bar) | 1 |

| Oil quantity hydr. fan (l/min) | 60 – 80 |

| Adj. drawbar linkage | Ring hitch Ø 58 – 79 mm |

| Ball-type linkage | K 80 |

*Weights of the machines in minimum equipment

Features

SD (SINGLEDISC) COULTER

versatile, Robust, precise

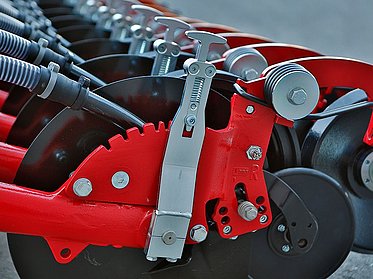

The individual depth controlled SingleDisc coulter has especially been designed for the Avatar line. Due to its individuality and flexibility, it can be adapted to the most different sowing conditions:

- Direct seed

- Mulch seed

- Conventional tillage

- In standing catch crops

- Stony and very heavy, clayey soils

The interaction of sincle disc coulter and seed skid guarantees a safe opening of the furrow. At the same time harvest residues are removed from the furrow. The result is an optimum contact of seed and soil for quick and safe emergence.

Via the rubber buffer a coulter pressure of up to 350 kg per coulter can be transferred. The coulter pressure can be adjusted mechanically or electrically via the terminal. All pivot points and connections at the coulter are maintenance-free. The durable, maintenance-free bearings at all turning parts guarantee a long service life and operational reliability. The seed skid is equipped with a carbide wear edge for a long service life. It can even be extended with the HM+ version.

The stable depth control rolls guarantee an exact depth control of the coulter in changing or difficult conditions. This is due to different co-ordinated adjustments of the seed coulter and optional equipments.

Due to the lateral inclination of 6° and an undergrip of 3° of the single disc coulter the seed is placed below the surface in a slanting way. Depending on the conditions you can choose between Uniformer and catching roller.

Uniformer

- Safe fixing of the seed in the furrow

- Flexible use

- Ideal when sowing into green catch crops

Catching roller in the row

- Safe emergence even in dry conditions

- High operational reliability even in very wet conditions due to the integrated parking position for the catching roller; the press wheel in this case is moved away from the working area

Depending on the soil conditions the angle of the closing wheel can be adjusted:

- Aggressively for direct seed or on very heavy soils

- Passively on cultivated or very light soils

You can choose between two versions:

Star wheel steel

- For sowing in very dry conditions the star closing wheel is the optimum solution

- The star wheel produces important fine earth for closing the seed furrow

Closing wheel steel

- For sowing in wet, changing conditions the steel closing wheel is ideal.

- Closes the seed furrow even in changing conditions

- Ideal with the offset method

- The down force of the closing wheels can be adjusted by means of a spring without any tools.