Terrano GX

Elegant precision in all its diversity

The Terrano GX is an all-rounder that works perfectly for shallow as well as for deep cultivation up to 25 cm.

The Terrano GX is available as a 3- and 4-bar universal cultivator and thus combines the requirements of every customer. The working widths range from 4 to 6 m. It is equipped with the TerraGrip tine of the third generation that is placed flatly in the frame and has a release force of 550 kg. The large pivot points guarantee a long and maintenance-free service life. The cultivator can be equipped with a lot of coulter versions so that it can be used in any season and in the most different soil conditions all over the world.

The chassis of the Terrano GX is located behind the tine section, in front of the levelling tools. The chassis with large tyres is used for road transport as well as for turning on the headlands. The sophisticated design characteristics of the chassis guarantees high ground clearance when lifted as well as a save swivelling of the tyres out of the working range when lowered. The position of the chassis has been chosen to guarantee optimum manoeuvrability in the field and high driving comfort on the road.

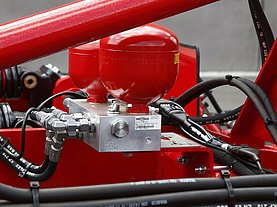

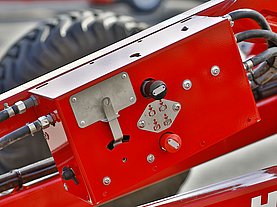

To make optimum use of the tractive output and get the existing power into the soil, the Terrano GX is equipped with a traction reinforcement that permanently applies a pressure of 1 200 kg on the rear axle of the tractor. If the traction reinforcement is not required, if you want to work more shallowly, it can be switched off anytime via a lock valve. It is activated by simply depressurising the control device for lifting and lowering without any additional control devices or cylinders.

With regard to levelling you can choose between the discs with oil-bath bearing that aggressively distribute the material in front of the packer and the levellers that spread the material and thus guarantee perfect levelling.

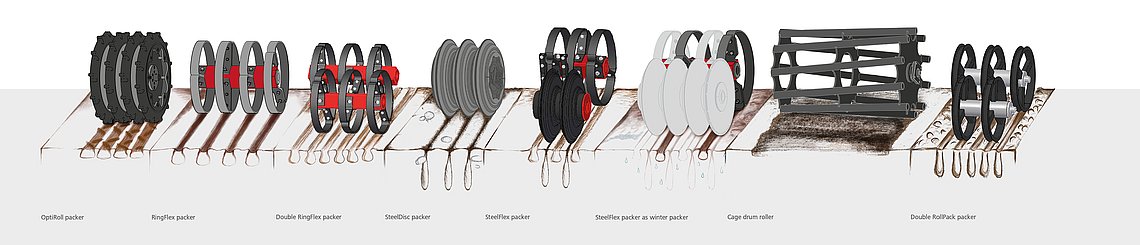

The Terrano GX can be equipped with a single packer or with a double packer. New packer versions have been developed that cover any range of use. For working in wet conditions or to cultivate the winter furrow, it is possible to dismantle every second ring of the RingFlex packer. The low contact area prevents consolidation and a clogging of the packer and controls the depth of the machine.

The packer range for the Terrano GX has been extended. The RingFlex packer, the SteelDisc packer, the cage drum roller and the new OptiRoll packer are available as single packers. The available double packer versions are the new SteelFlex packer, the double RingFlex packer and the double RollPack packer.

Terrano GX

Extremely low horsepower requirement!

Terrano GX – Elegant precision in all its diversity

The Terrano GX has been developed for efficient and accurate tillage. The scope of use ranges from shallow tillage to deep tillage up to 25 cm. It is available in a 3- and a 4-bar version. Due to the simple handling and the structured design together with an optimum working result the machine is an uncompromising tool for all requirements.

Beside the in-house development SteelFlex packer, further single and double packer versions are available for consolidation.

HORSCH Milestone – Farming without a plough

During the 30-year-old company tradition HORSCH – like no other manufacturer – contributed to the breakthrough of tillage without a plough . In 2013, these efforts were awarded with the “ Milestone of Agricultural Engineering ” award. A lot of products, e. g. the Terrano, Tiger and Joker models and last but not least the universal seed drill Pronto DC, allow for farming without a plough on the highest level. According to the Federal Statistical Office by now 40 per cent of the arable land is cultivated without a plough. For wheat it amounts to even 60 per cent. 20 years ago no-one dared to believe that. HORSCH played an important part in getting this far. With this background other milestones in agricultural engineering will be developed.

What are the excelling features of the Terrano GX?

- 3- and 4-bar universal cultivator

- For shallow and deep working

- Manoeuvrable due to middle chassis

- Low horsepower requirement

- TerraGrip III tines

- Standard traction reinforcement

- Variable packers

TECHNICAL SPECIFICATIONS

| HORSCH Terrano GX | 4.3 GX | 5.3 GX | 6.3 GX |

| Working width (m) | 4.00 | 4.90 | 5.90 |

| Transport width (m) | 2.99 | 2.99 | 2.99 |

| Transport height (m) | 2.83 | 3.36 | 3.85 |

| Length (m) | 8.61 | 8.61 | 8.68 |

| Axle load (kg)* | 4 100 – 5 400 | 4 700 – 5 900 | 5 600 – 7 250 |

| Support weight (kg)* | 600 – 950 | 650 – 1 400 | 750 – 1 500 |

| Tyre size support wheels | 400 / 60 – 15.5 | 400 / 60 – 15.5 | 400 / 60 – 15.5 |

| Tyre size chassis | 550 / 45 – 22.5 | 550 / 45 – 22.5 | 550 / 45 – 22.5 |

| Number of tines | 13 | 16 | 19 |

| Tine spacing (cm) in one row | 92 | 94 | 95 |

| Tine spacing (cm) | 31.00 | 31.00 | 31.50 |

| Frame height (mm) | 850 | 850 | 850 |

| Double-acting control devices | 2 (+ 1 with hydr. depth adjustment) | ||

| Power demand (kW/hp) from | 130 / 175 | 175 / 240 | 220 / 300 |

| Connection via lower link | Cat. III – III / IV – IV | Cat. III – III / IV – IV | Cat. III – III / IV – IV |

| Connection via adjustable drawbar | Hitch Ø 42 – 51 mm | Hitch Ø 42 – 51 mm | Hitch Ø 42 – 51 mm |

| Connection via ball hitch | K 80 | K 80 | K 80 |

* Weight of the machines with minimum / maximum equipment

| HORSCH Terrano GX | 4.4 GX | 5.4 GX | 6.4 GX |

| Working width (m) | 4.00 | 4.90 | 5.90 |

| Transport width (m) | 2.99 | 2.99 | 2.99 |

| Transport height (m) | 2.83 | 3.36 | 3.85 |

| Length (m) | 9.40 | 9.40 | 9.40 |

| Axle load (kg)* | 4 250 – 5 650 | 4 850 – 6 800 | 6 100 – 7 700 |

| Support weight (kg)* | 700 – 1 300 | 800 – 1 500 | 800 – 1 800 |

| Tyre size support wheels | 400 / 60 – 15.5 | 400 / 60 – 15.5 | 400 / 60 – 15.5 |

| Tyre size chassis | 550 / 45 – 22.5 | 550 / 45 – 22.5 | 550 / 45 – 22.5 |

| Number of tines | 13 | 17 | 21 |

| Tine spacing (cm) in one row | 123 | 118 | 114 |

| Tine spacing (cm) | 31.00 | 29.50 | 28.50 |

| Frame height (mm) | 850 | 850 | 850 |

| Double-acting control devices | 2 (+ 1 with hydr. depth adjustment) | ||

| Power demand (kW/hp) from | 185 / 250 | 220 / 300 | 260 / 350 |

| Connection via lower link | Cat. III – III / IV – IV | Cat. III – III / IV – IV | Cat. III – III / IV – IV |

| Connection via adjustable drawbar | Hitch Ø 42 – 51 mm | Hitch Ø 42 – 51 – 71 mm | Hitch Ø 42 – 51 – 71 mm |

| Connection via ball head | K 80 | K 80 | K 80 |

* Weight of the machines with minimum / maximum equipment

Features

TerraGrip

Solid safety

The TerraGrip is a very powerful tine with overload protection. The trip height amounts to 30 cm without triggering a shear bolt. This saves time and money. Due to the effective stone protection the tine moves quickly in case of overload and due to the spring force penetrates the soil again quickly and exactly – without the usual side movements.

When avoiding an obstacle, the force of the spring decreases from 550 kg to 175 kg. The force that acts on the frame is thus reduced considerably. The optimised spring kit allows for an exact point control in the desired working depth – even in heavy soils and large working depths. Due to high-quality material and large pivot points any greasing points become unnecessary.

HORSCH

Point versions for any use

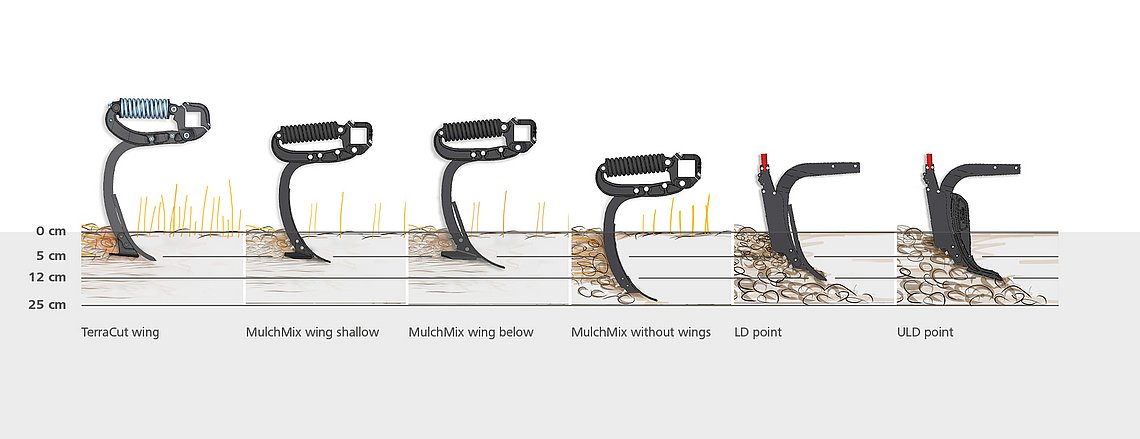

The MulchMix point with its steep angle is designed for the intensive mixing of harvest residues and deep cultivation. Due to the large diameter (600 mm) of the HORSCH MulchMix point the soil is not pressed and its structure remains intact. Regardless of the working depth: The point never penetrates the soil vertically. This reduces the horse power requirement and saves valuable petrol. Even if there are high amounts of straw, it achieves an excellent mixing quality. The MulchMix points consist of three parts (point, guide plate, wing) which can be changed independently.

For a very shallow stubble cultivation and all-over cutting the wings can be set to a shallow position. If deep loosening and at the same time an excellent mixing of the soil is desired, the wings can simply be dismantled.

If deep loosening without mixing is desired, the machine can be equipped with HORSCH LD points which guarantee excellent loosening up to 25 cm without moving too much earth. Another option is the HORSCH ULD points that due to its shape does not takes clods to the surface, but only loosens the soil deeply.

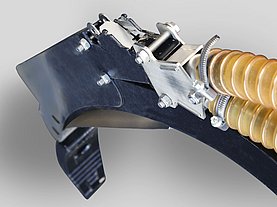

The newly developed HORSCH TerraCut point is used for shallow, all-over tillage at a maximum depth of 8 cm. The 40 cm wide wing is combined with the well-known LD or LD+ point and can be used on all HORSCH TerraGrip tines shafts. The shallow setting angle of the TerraCut point guarantees a safe cutting effect and a low mixing effect for an efficient drying of growth or catch crops.

If deep loosening without mixing is desired, the machine can be equipped with HORSCH LD points which guarantee excellent loosening up to 25 cm without moving too much earth. Another option is the HORSCH ULD points that due to its shape does not takes clods to the surface, but only loosens the soil deeply.

Packer

FOR THE OPTIMUM RESULT

HORSCH can supply the appropriate packer version for deep as well as for shallow consolidation. The choice of the packer depends on the soil and HORSCH has a reasonable solution for any type of soil. Due to the consolidation excessively loose soil is compacted, clods are destroyed and an ideal environment with an optimum ratio of water- and air-bearing pores is created.

The new SteelFlex packer has been developed for the Terrano GX to provide more flexibility. The SteelFlex packer is a mixture of SteelDisc and RingFlex.

The SteelDisc roller provides a deep consolidation to guarantee an optimum connection to the water supply, the RingFlex packer then covers the surface with fine earth for an optimum germination bed.

Bearing stub

- Exchangeable bearing stubs at each packer

- Simple, fast and cost-efficient

- Bearing can be changed easily

- Bearing stub can easily be replaced if necessary

The following packers are available for the Terrano GX:

OptiRoll packer, RingFlex packer, double RingFlex packer, SteelDisc packer, SteelFlex packer, SteelFlex Packer as winter packer, cage drum roller and double RollPack packer.

Why it the appropriate packer important for your machine?

- Central element to determine the working quality

- Depth control

- Different consolidation depending on the requirements

- Perfect working quality in wet and dry conditions

- Appropriate germination bed for volunteer crops and weeds

- Rough, loose soil structure for medium and heavy soils

- Final finishing of the seed horizon

Additional Features

MiniDrill

Accurate efficiency for catch crops and Greening

The HORSCH MiniDrill is a completely new development. It is equipped with a 400 l hopper and the well-proven metering unit of the Pronto. The seed is injected directly into the distribution system. The MiniDrill can be combined with all Terrano FX and GX machines.

To guarantee an excellent lateral distribution there are six evenly distributed outlets in front of or behind the packer for 3 m machines and twelve outlets for 4 m working width upward.