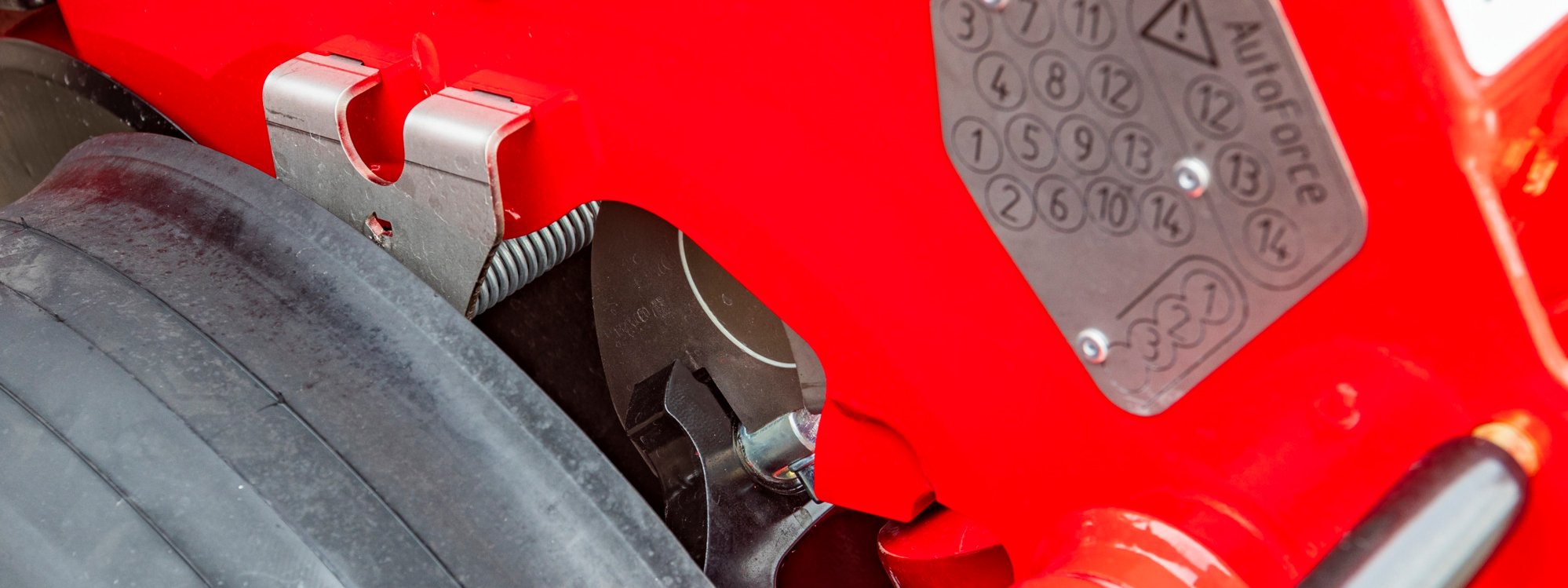

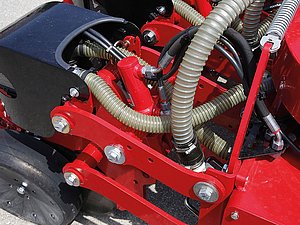

All HORSCH Maestro row crop planters feature hydraulic row unit downforce as standard equipment. Another standard feature on all Maestro row crop planters is the weight transfer system, stabilizing the toolbar which in turn provides stabilization for the row unit. The amount of row unit downforce desired can be easily manually adjusted from the planter monitor. Down pressure adjustments are necessary to maintain proper seed depth placement and to prevent side wall compaction. When planting into variable soil density conditions, the optional HORSCH AutoForce system integrates with the standard hydraulic downforce system allowing automatic downforce adjustment as soil density changes during planting. Based upon field condition observations by the operator, parameters for desired weight on the gauge wheels are set for the automatic system.

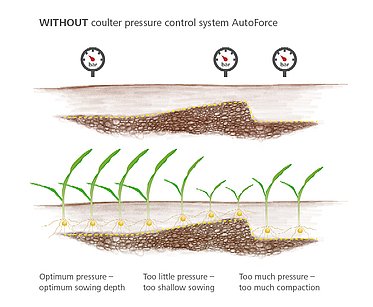

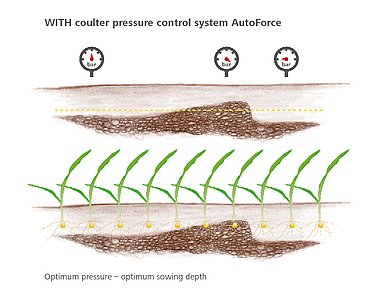

HORSCH AutoForce uses strain gauge sensors to measure weight being applied to the gauge wheels. To maintain precise seed depth control and to maintain furrow integrity, the row unit must keep a consistent amount of weight applied to the gauge wheels. If there is not enough weight on the gauge wheels, shallow and inconsistent seed depth placement can occur which puts yields at risk. If there is too much weight on the gauge wheels excessive side wall compaction can occur, restricting root growth and putting yields at risk. Based upon the pre-set desired gauge wheel weight in the monitor, AutoForce quickly adjusts as soil density changes in order to maintain consistent weight on the gauge wheels. By automatically adjusting weight on the gauge wheels while planting in variable density soils proper seed depth and furrow integrity are maintained, ensuring seed are placed into an optimum environment set for maximum yield potential.

While planting, the HORSCH AutoForce system gives immediate performance feedback on the planter monitor. Visual inspections of the furrow will always be needed when choosing parameters for AutoForce operation. All functions, settings, and diagnostics are easily done through the planter monitor. Use AutoForce in fields that have variable soil density due to inconsistent compaction, dry hard soils, or into no-till conditions. When planting into well prepared seedbeds that have a uniform soil density, AutoForce can be simply used in a manual mode.

AutoForce excels due to its simplicity and overall ease of operation. By stabilizing the toolbar with the weight transfer system, and standard hydraulic downforce as standard equipment, AutoForce has the superior platform to perform. The system is divided into sections, with the ability to set independent gauge wheel weight parameters for the tractor wheel track path.