The first mechanical HORSCH seed drill excels due to technical innovations in the metering and tramline control sector.

DLG APPROVED 2023: Test report for the mechanical seed drill Versa 3 KR

The mechanical seed drill Versa 3 KR was awarded the quality mark DLG APPROVED 2023 in the DLG test report 7413. It impressed due to very good results for the DLG test criteria “Functionality and quality of work” as well as “Handling, operation and maintenance”. The award was presented at the Agritechnica 2023.

Professional seed drill with 3-point linkage

- Different and fast to configure tramlines due to SmartClip metering system

- ISOBUS-based calibration and operation of the machine

- Due to new operational concept display options can be customised

- Capacity of 900 l, can be extended with optional hopper attachments

- 12.5 cm and 15 cm row spacing are available

- DuoDisc double disc seed coulter consisting of well-proven components of the TurboDisc III seed coulter

- Coulter pressure up to 50 kg

- Optional heavy harrow for closing the seed furrow in extremely difficult and wet conditions

PTO-shaft driven tillage with the rotary harrow Kredo allows for an intensive seedbed preparation even in difficult conditions. The rotary harrow Kredo has 10 rotors on 3 m working width. Its robust design is ideal even on stony soils. With quick-change tines, it can be equipped with drag or grip tines. Tines with carbide coating are available to ensure a long service life. The well-proven coating technology from the cultivator tine products is used. The finely graduated adjustment of the working depth for the rotary harrow is easily accessible from the outside and is clearly visible. The adjustment of the levelling bar, too, is very easy.

- Universal range of applications after plough

- For mulch seeding even on extremely heavy soils

- After conventional tillage

- On stony and very heavy clayey soils

Datos técnicos

| Horsch Versa | 3 KR |

| Working width (m) | 3,00 |

| Transport width (m) | 3,00 |

| Filling height (m) | 1,86 |

| Length without/with pre-emergence marker (m) | 2,85 / 3,25 |

| Weight (kg) | 2700 - 3500 |

| Seed hopper capacity single hopper (l) | 900 |

| Dimension of feed opening (m) | 2,80 x 0,90 |

| Number of seed coulters (Piece) | 20 / 24 |

| Coulter pressure (kg) | 5 - 50 |

| Row spacing (cm) | 15,0 / 12,5 |

| Packer trapeze ring roller Ø (cm) | 50 / 60 |

| Packer tooth packer Ø (cm) | 64 |

| Number of rotors (Piece) | 10 |

| Operational speed (km/h) | 5 - 12 |

| Horsepower requirement (kW/hp) | 110 - 185 / 150 - 250 |

| DA control devices | 0 (+1 bout marker / +1 pre-emergence marker) |

| Implement attachment | 3-point Cat. III |

Equipamiento básico

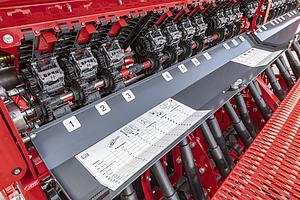

SmartClip metering system

Reliability and diversity

- Technical innovation in the metering and tramline control sector

- Metering wheels can be removed without any tools

- Simple change of the row spacing

- Flexible pre-selection of tramlines without any tools

The main focus of the electrically driven metering unit is on the drive shaft. The individual connection of the metering units allows for changing the tramlines individually without any tools. In addition, different row spacings are possible, e.g. 15 cm to 30 cm or 45 cm. Depending on the seed, the metering unit can easily be adjusted with a stop between spacing wheel and cam wheel. The metering wheels, too, can be removed individually and without tools for checking.

Application rates with SmartClip:

- Minimum seed rate for fine seeds: 1.5 kg/ha, with double row spacing 0.8 kg/ha

(at 4 km/h. At higher speeds lower application rates are possible.) - Maximum seed rate for cereals: 450 kg/ha, with double row spacing 225 kg/ha

(at 10 km/h. At lower speeds, higher application rates are possible.)

DuoDisc seed coulter

The light-weight double disc coulter

- Light double disc seed coulter with a coulter pressure of up to 50 kg

- Double disc coulter

- Creates a precise seed furrow

- Press wheel controlled (5 cm or 7.5 cm wide)

- Uniformer ensures the seed grains stays in the furrow

- Inside scraper prevents blocking and clogging of the coulter

- Allows for a even and safe emergence

A perfect embedding of the seed and an immediate seed-soil contact are the prerequisites for a safe and regular emergence. The double disc seed coulter that has been developed on the basis of the TurboDisc seed coulter impresses with its precise seed placement and the well-proven components. The press-wheel-controlled coulter design allows for an excellent following of the soil contours. This is the only way to keep the placement depth for every single seed grain.

The double disc seed coulter with maintenance-free bearing opens the soil and thus allows for accurate seed placement. The integrated uniformer ensures a fixing of the seed at the bottom of the seed furrow - even at high operational speeds. A movable, carbide coated scraper keeps the area between the discs clean and prevents clogging even in sticky and wet conditions. The 5-cm or 7.5-cm-wide press wheel guarantees optimum seed-soil contact and a precise exact depth control.

In addition to the excellent adaption to the soil, the DuoDisc seed bar impresses with its easy operation: coulter pressure and sowing depth do not influence each other when being adjusted. The maintenance-free metal spring of the seed coulters transfers a coulter pressure of up to 50 kg and thus ensures a precise seed placement behind the rotary harrow. Moreover, the suspension acts as an overload protection and shock absorber for stones.

Kredo rotary harrow

Active seedbed preparation

- Long service life due to solid and massive gear unit

- Tines can be changed without any tools

- 10 rotors for maximum clearance for 3 m working width

- Actively driven seedbed preparation for different requirements

- Targeted control of the cultivation intensity in the seedbed by adapting the working speed and the rotational speed of the rotary harrow (standard 244 or 306 rpm)

- Solid and massive gear unit and drive for highest stresses in the field

- Targeted control of idle time and working effect: tines are arranged draggingly for seedbed preparation on intensely cultivated fields:

- Standard tine

- HM tine (reinforced for long service life)

- HM+ tine (maximum wear protection with carbide technology from the cultivator sector)

- Tine on grip for aggressive cultivation of solid soils

PTO-shaft driven tillage with the rotary harrow Kredo allows for an intensive seedbed preparation even in difficult conditions. The rotary harrow Kredo has 10 rotors on 3 m working width. Its robust design is ideal even on stony soils. With quick-change tines, it can be equipped with drag or grip tines. Tines with carbide coating are available to ensure a long service life. The well-proven coating technology from the cultivator tine products is used. The finely graduated adjustment of the working depth for the rotary harrow is easily accessible from the outside and is clearly visible. The adjustment of the levelling bar, too, is very easy.

Trapeze ring packer

- Ideal in changing conditions

- For a targeted consolidation in front of every seed row

- In wet conditions, scrapers clean the packer roller

The trapeze ring packer has a diameter of 50 cm for heavy soils with a targeted consolidation or 60 cm for changing soils from light to heavy with high requirements for load-carrying capacity. It forms a perfect seed furrow even in heavy and cohesive conditions.

Equipamiento adicional

Heavy harrow

Extreme conditions require special solutions

- Ideal solution for late sowing in wet conditions

- Easy, flexible adjustment without any tools

- Aggressive and passive working position possible

- Easy to deactivate with HORSCH clips in lifted position

When sowing very late and if the conditions are wet, e.g. after grain maize or sugar beet, the optional heavy harrow with its cranked tines ensures a transverse movement of the soil and thus securely covers every seed grain.

The heavy harrow can be adjusted flexibly – very passively for shallow sowing of seeds that require light for germination or very aggressively with a lot of pressure in case of late, wet sowing times. To this end, you can easily and without tools turn the pressure spring of the harrow to place weight on the harrow or to remove weight from the harrow. The aggressiveness of the tines is adjusted via two hole system. Two HORSCH clips are plugged in between bracket and hole system to work without a harrow.

Hopper extensions

Increased efficiency due to reduced filling stops

- Hopper extension for 1 200 l or 1 500 l hopper capacity

- Increased efficiency

- Reduces filling stops

The Versa KR excels due to its simple and light design. With the optional hopper extensions the hopper capacity can almost be doubled.

There are two different hopper attachments: for 1 200 l hopper capacity or for 1 500 l hopper capacity. The larger hopper capacity increases the efficiency of the machine and the filling stops are reduced.

Electric half-width shut-off

Seed savings due to precise switching off of the half-width

- Simple switching on/off of the half-width via the user interface is possible

- Automatic SectionControl is possible

- Flexible in case of asymmetric tramlines

- Saves operating material by precisely switching off the half-width in case of short work and obstacles

The option of a half-width shut-off allows for saving fertiliser and seed. For this purpose, the drive shaft is divided and controlled by a drive motor per machine half . Avoiding overlaps in short work or obstacles improves the development of the individual plant and reduces the disease and competitive pressure in these areas. by reducing the seed quantity, costs for operationg material are reduced.

WorkLight Pro

Best visibility at night

- Optimal illumination of the working surroundings at twilight and at night

- Flexibly adjustable LED headlights

- Can be switched on/ off via the terminal

- Very good illumination with low energy requirement

Flexibility plays an important role while sowing as you should choose the perfect sowing time for an optimum population. When sowing late or early, WorkLight Pro guarantees an optimum illumination of the area behind the seed drill combination.