TurboDisc

TurboDisc – the third generation guarantees an advance in seed placement

A perfect embedding of the seed and an immediate seed-soil contact are the basic requirement for a safe and homogeneous emergence. HORSCH perfectly meets the challenge to achieve this aim even at high speeds. The solution is called TurboDisc . The double disc seed coulter that has been used for more than 20 years and is constantly developed further convinces by its precise seed placement. The press-wheel-controlled coulter design allows for a quick adaption to the soil contours at high speeds. Thus, the set placement depth can be kept up for every single seed grain.

The double disc seed coulter with the maintenance-free bearing opens the soil and thus allows for an undisturbed seed placement.

The integrated Uniformer guarantees the fixation of the seed at the bottom of the seed furrow even at high operational speeds. A carbide coated scraper keeps the area between the discs clean and thus prevents cloggings even in adhesive and wet conditions. Finally, the 5 or 7.5 cm wide press wheel provides an optimum seed-soil contact and an exact depth control.

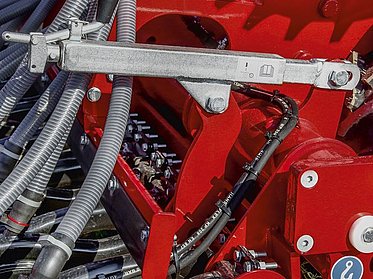

In addition to the excellent soil adaption, the TurboDisc seed bar excels due to its simple handling: the adjustment of the coulter pressure does not influence the seed depth and vice versa. The maintenance-free rubber bearing of the seed coulters transfers a coulter pressure of 120 kg and thus guarantees a steady coulter – up to an operational speed of 20 km/h. Moreover, the rubber bearings acts as an overload protection and a shock absorber for stones.

Side view packer and seed coulter

Uniformer and scraper

Secure seed placement in wet conditions

Effective coulter shock absorption

Maintenance-free, minimum

wear and tear mounting

Stepless coulter pressure adjustment

Manual adjustment increases the pre-load of the rubber elements

DoubleDisc coulter

Straight discs with inner maintenance-free bearings

Shock absorbed mounting

Good contour-following capability and overload protection