Our standard:

No hose is the best hose.

Distribution system

- Optimal supply of boom, induction hopper, intensive agitator and inside tank cleaning

- Only one hose for the entire boom width and one return flow hose for wash circulation in the boom

- No deposits and easy cleaning

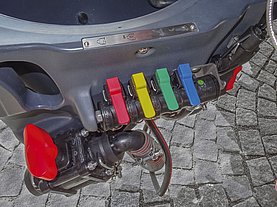

Induction hopper

- Powerful injector filling

- Swiveling induction hopper with hydraulic damped lowering and a stainless steel bowl.

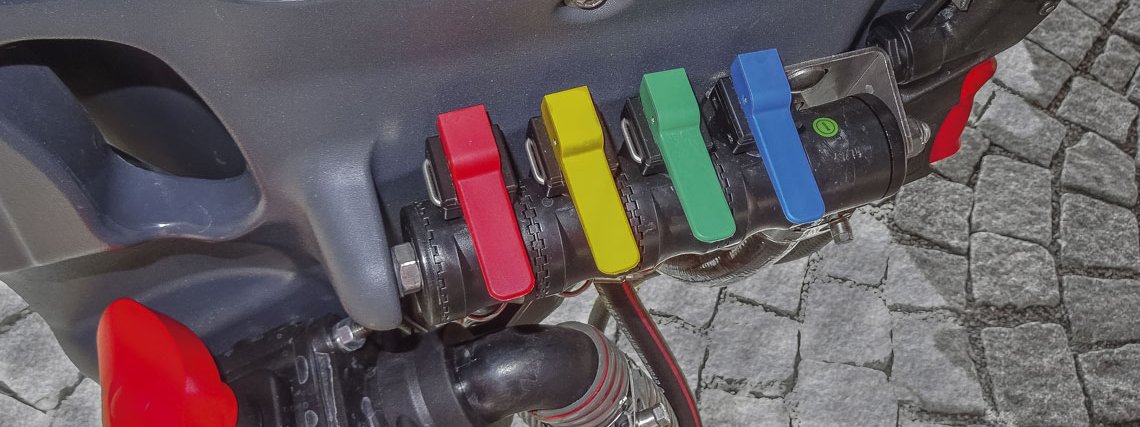

- Toolbar with coloured control levers

- Upper and lower rinsing nozzles guarantee a whirl-like circulation for quick flushing-in of liquids. Also suitable for granulate.

- Cleaning nozzle

- Optional: induction tank pot made of stainless steel with more capacity and additional shock nozzle

Circulation system + nozzle cleaning

- Circulation of the chemical solution through the complete nozzle tube as soon as the spraying pump is switched on.

- Spraying fluid therefore is always at the nozzle, even with the spraying apparatus switched off

- When switching on a section or the entire spraying line for the first time, the chemical solution is directly and in a well-mixed way available in the partial system or in the entire spraying system.

- Prevents deposits and blockages

- Enables simple cleaning: The suction side of the pump is set to fresh water – the nozzle line is thus flushed with clear water – then keep spraying for about 3 seconds to clean all nozzles.

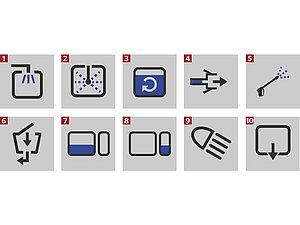

Leeb TD equipment line CCS Pro – cleaning programs

- Several selectable cleaning programs can be started simply and comfortably by pressing a button in the cabin:

Complete cleaning: Rinses injector line via the filter to the boom completely with fresh water and then continues with the continuous inside cleaning (CCS) for mixture tank and boom.

Dilution: Dilute the spraying mixture in the desired ratio without much effort.

Intensive washing program: For a particularly thorough cleaning – recommended for example when changing between critical crops.

Boom cleaning: Automatic rinsing of the boom – e. g. when the work is interrupted for several hours

Background cleaning: Intelligent, continuous inside cleaning that cleans the inside wall of the tank with fresh water while spraying. This prevents deposits at the barrel wall.

- Due to the standard automatic two filling limits the filling procedure is rather relaxed

- Agitator works and switches off automatically depending on the filling level

![[Translate to englisch:] [Translate to englisch:]](/fileadmin/_processed_/f/e/csm_20922_88a0b65a4a.jpg)

![[Translate to englisch:]](/fileadmin/_processed_/e/c/csm_18693_ce76725ac1.jpg)