Leeb PT Frame and cabin

At the Agritechnica, end of 2019, we presented a new PT platform. Many farmers rely on the self-propelled HORSCH LEEB sprayers, for the name has been standing for innovative technology, ease of use and optimum adaptability to the requirements of our customers for almost two decades.

With the new PT we took another step towards the future of plant protection. As usual HORSCH does not only concentrate on the big picture but also on the details. For the details facilitate working and guarantee an increase of efficiency. We want to explain some of these exciting details.

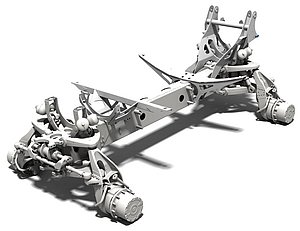

Our engineers developped a chassis concept that has specifically been designed to meet the requirements of a modern, self-propelled plant protection sprayer. The ComfortDrive chassis is based on an individual wheel suspension and a hydro-pneumatic suspension. The driver, thus, is untroubled by impacts and enjoys utmost comfort and driving stability. Moreover, the new triangular control arm axle arms guarantee maximum flexibility for all challenges – in the field or on the road. The driver can lift the machine hydraulically from the cabin to a clearance height of 135 cm or lower it if necessary, e.g. when driving in hilly terrain. As soon as the PT has to drive on the road, you only have to press the road control switch and the PT automatically adapts the transport height to under 4 m.

The self-propelled sprayer does not only set new standards with the ComfortDrive chassis, but also with the cabin. The cabin can be equipped with safety class system IV and due to an adjustable overpressure fan and an activated carbon filter protects the driver from dust, aerosols and vapours in an optimum way. Up to 12 LED working lights around the cabin allow for using the self-propelled sprayer at the treatment time that is optimum for the plant. To adapt the plant protection measures to the plant in an optimum way, the new cabin does not only offer protection, light and an optimum circumferential visibility, but also utmost functionality. This includes for example the ISOBUS concept with HORSCH job computer and software that are custom-tailored to the requirements of the customer. The ISOBUS interface allows for using a terminal of the farmer’s choice. Thus, brands/terminals that already exist on the farm can be used. This may facilitate for example to share data and to retransfer collected data.

The ErgoControl armrest that is operated intuitively guarantees that the driver has everything under control even on long working days and can concentrate first and foremost on the populations. It includes the new joystick that has been optimised with regard to the shape of the hand to always have the most important functions in hand. All buttons of the joystick are backlit and arranged according to their functions. The nozzles, the boom heights, the sections and two speed controls can be operated via the joystick. Two softkeys complete the operating environment. The PT adapts to you and not you to the PT!