Crop Protection: More nozzles, more options!?

More nozzles, more options!?

Taking into consideration that more and more plant protection agents are taken off the market, application has to improve and to become more target-oriented. Depending on the plant protection agent and the crop, we recommend different nozzles as the wetting has to be adapted to the different modes of action of the plant protection agents to achieve an optimum effect.

Of course, the current stipulations and laws have to be considered!

In farming two types of nozzles are usually used for application: the flat jet nozzle and the double flat jet nozzle. Both have their preferred range of use which they have been designed for. With a flat jet nozzle, you can achieve a deep effect in the population as the jet penetrates the population vertically. Thus, there is an even distribution at the top of the population. With a double flat jet nozzle, however, the jet is separated in one forward-facing and one backward-facing jet which allows for an excellent wetting of leaves and the soil. By wetting the plants and the soil from the front and from the rear, they are sprayed from both sides. The deep effect is not so pronounced because of the gravity centre of the wetting.

These two nozzles cover most requirements of plant protection agents. The double flat jet nozzle is ideal for applying soil herbicides or contact fungicides as they „wrap up“ the plant in an optimum way due to the good wetting described above. The nozzles are often used to apply pre-emergence herbicides. The advantage of the flat jet nozzle mainly is the deep effect described above. An optimum example of use is deep-rooted mildew at the basis of the stalk in the flag leaf stage. Due to its vertical direction the single jet can penetrate deeply into the population and thus can still reach the basis of the stalk even in an advanced development stage of the population.

Previously, this often required changing the nozzles what is very time-consuming. Being a manufacturer of innovative plant protection technology HORSCH LEEB, for several years, has been offering the possibility to carry along several nozzles on one boom – not only via manual multiple nozzle carriers but also via pneumatic multiple nozzle carriers. So there is no need for a time-consuming change.

With the BoomControl boom and AutoSelect HORSCH LEEB offers various nozzle combination options and several possibilities for an automatic adaptation of the nozzles to the operating conditions. We will describe a nozzle combination for a 2-2 layout of the boom with AutoSelect and explain the possibilities of this combination.

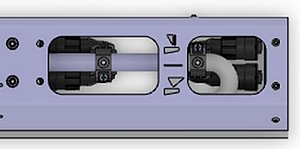

For HORSCH LEEB a 2-2 nozzle layout means that every 50 cm two nozzles are mounted at the main nozzle carrier. Moreover, another two nozzles are mounted at the secondary nozzles between the main nozzles. This results in a nozzle spacing of 25 cm, every 50 cm there are 4 nozzles. Due to these 4 nozzles spots there are numerous possibilities to equip the boom with nozzles and to combine them. Based on long-time experience and the close contact to the farmers our nozzles consultants found a very good combination.

Holger Piehler from the HORSCH Zentrum regularly uses one 80° flat jet nozzle calibre 02 every 25 cm for the first assembly. Some manufacturers developed nozzles that dispose of a very large constant pressure range of 2 to 8 bar with a drift reduction of 90 %. With a nozzle spacing of 25 cm the 80° angle guarantees the desired triple overlapping and thus a perfect application. Another advantage of this nozzle is that due to the 80° angle it has a large share of rough drops in the drop spectrum via a wide pressure range. This additionally counteracts drift. The effect can be illustrated if we take the jet of a high-pressure cleaner as an example. The larger you expand the jet of the high-pressure cleaner the larger is the share of fine drops in the peripheral area. This results in another advantage of the 80° nozzle in combination with a 25 nozzle layout. The more acute angle reduces travel time and distance. The way of the drop in the air is shorter and the drop gets faster to the target area. This minimises the influence of disturbing factors like evaporation, thermal and dust. With these nozzles every 25 cm the operational speed can be increased to 16 km/ with 150 to 200 litres per hectare. Some crops, however, require an increased application rate, e.g. for the flower treatment of rape. However, you have to observe the stipulations as the operational speed for these agents often is restricted. Thus, the nozzles still are sufficient.

The 80° 02 flat jet nozzle is the optimum choice for a 25 layout to penetrate the populations as it disposes of a rough drop spectrum but still achieves the desired penetration depth.

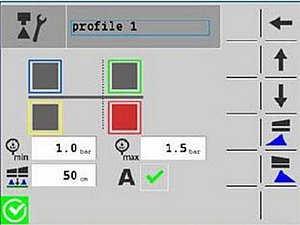

Now there are still two nozzle spots at the boom that are not used. At the free spots of the main nozzle carrier we mount a compact 04 double flat jet nozzle. Especially for soil herbicides and contact fungicides, this nozzle guarantees an excellent wetting and a drift reduction up to 90 %. However, the pressure range of the nozzle is limited to a maximum of 3 bar. This is where AutoSelect which we mentioned above comes in. A lot of different profiles can be created depending on the nozzle and the operational speed.

An example: A farmer drives in the pre-emerged population with a soil herbicide: one 04 nozzle every 50 cm, operational speed: 10 km/h. The pressure is 2.5 bar. The nozzle thus is admitted for 90 % drift reduction and the drop spectrum is ideal. If the customer drives faster, the pressure will leave the allowed range, loose the drift reduction and the drop spectrum will deteriorate. The result would be an unnecessary damage to the environment and a bad wetting. With AutoSelect the user can define that another nozzle opens as of a speed of for example 11 km/h. As there still is one free nozzle spot, we recommend a 025 double flat jet nozzle. There are several nozzles that are approved by the JKI with a drift reduction of 90 %. Thus, depending on the application, the customer can work with two double flat jet nozzles every 25 cm and thus realise higher operational speeds or higher application rates. For arithmetically he has combined a 04 double flat jet nozzle and a 025 double flat jet nozzle to a 065 double flat jet nozzle. Thus, the drop spectrum remains in an optimum range and at the same time, the wetting is optimum again. Another advantage of AutoSelect is that the boom height for the individual profiles can be saved. Thus, when switching from a 04 nozzle to a 04 and 025 double flat jet nozzle the boom automatically reduces the boom distance from 50 cm to 30 cm. This is an essential step to keep up the triple overlapping and to counteract drift due to the increased operational speed.

Moreover, many farmers more and more rely on applying liquid fertiliser as by means of SectionControl the fertiliser can be applied in a high-precision way and at the boundaries. The farmer has two options: As liquid fertiliser mainly is applied in spring, one nozzle can be replaced by a liquid fertiliser nozzle. Thus, the fertiliser can be applied with the appropriate nozzle. If the farmer does not want to replace the nozzle, all nozzles can be opened by means of AutoSelect and the application is carried out with an arithmetical 10 nozzle. Or the customer chooses the option 2-2 4-fold manual. He then can carry along 4 nozzles on one nozzle carrier and by turning can move 2 of the 4 nozzles respectively into the spraying position. Or he chooses option 4-2 when buying the sprayer. With both options the farmer can choose a liquid fertiliser nozzle and one other nozzle at the boom.

Due to this flexibility the user can take almost all required nozzles with him, react to all situations and save set-up times. The huge advantage for arable farmers is that no retrofitting is required even if the requirements on the nozzles and the sprayers change fast. Thus, application can always be carried out on schedule and save operating resources.

Because of the changing working heights that are adjusted automatically via AutoSelect there might be a problem at the boundaries. If the boom lowers to 30 cm the overlapping at the boundary will be too little and thus the plants will be wetted irregularly. Due to the double edge nozzle stock that is a HORSCH LEEB standard equipment a normal nozzle can be mounted for an optimum overlapping or an edge nozzle for the treatment of the boundaries which then stops exactly at the field boundary. This allows for a perfect application in the field as well as on the boundaries.

With a nozzle spacing of 25 cm or 50 cm and a large selection of nozzle carriers we have the custom-made solution for each farmer which he needs for his farm. For with a HORSCH Leeb plant protection sprayer you have more nozzles and more options. Your application is carried out in an optimum way, on schedule and environmentally friendly.