Pronto DC – well prepared for different conditions (III)

Average reading time: 5 min

Depending on the soil, the preparatory work and the crops that have to be drilled there are individual equipment versions for every customer. Thus, the machine can perfectly be adapted to the specific conditions with the objective to optimize the work result for the respective site.

Frontpacker, Crossbar & Co

Lowest possible track depths of the tractor in the seedbed guarantee good plant populations and reduce the horsepower requirement of the Pronto DC even more. The tyre packer that can be mounted additionally in front of the tine section takes up the weight of the machine, relieves the rear axle of the tractor and additionally levels the surface. This guarantees that the rotary harrow can work more shallowly thus saving tractive power and fuel. The optional telescopic drawbar allows for a 90° angle on the headlands even if an additional tyre packer is mounted.

Instead of the tyre packer you can also choose a Crossbar in front of the tine section. It is particularly ideal for being used on ploughed soils. The soil surface is levelled, and the clods are broken.

The right seed coulter for my conditions

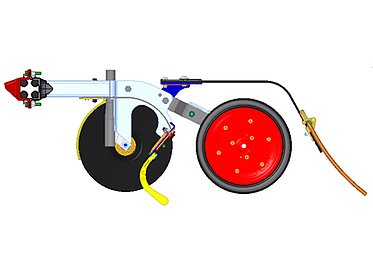

The well-proven HORSCH TurboDisc seed coulter of the 3rd generation is a completely in-house manufactured double disc coulter which preforms a V-shaped seed furrow and guarantees a precise placement of the seed at high operational speeds of up to 20 km/h.

The large clearance between the seed tube and the mobile scraper allows for an optimum self-cleaning of the disc blades in wet conditions. This design guarantees a long service life of the machine.

The rubber cord fixing allows for a quick and precise adaption to the soil contours. Coulter pressures between 20 and 120 kg can be realised via spindles or hydraulically as an option. But the saying less is more also applies in this case. The focus has to be on the right adaption of the embedding. The last part is the Uniformer that fixes the seed additionally in the seed furrow.

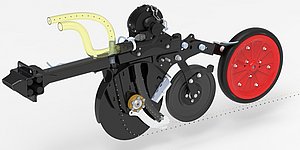

The PowerDisc Schar our Serto SC and Taro 6 HD are equipped with as standard is ideal for more extreme applications and thus it is perfect for sowing in difficult conditions. A safe seed placement even in a coarse seedbed and on heavy, stony soils is guaranteed. This is due to the response time of the parallelogram coulter as well as to the coulter pressure of up to 150 kg. The large bearings and the design of the coulter guarantee high stability and durability.

The HORSCH SingularSystem is a technology for the singulation of cereals and precise sowing. The design is similar to the well-proven TurboDisc coulter and in addition is it equipped with an integrated skid and a height-adjustable catching roller. The skid shapes the seed furrow and guarantees an exact placement of the seed. The catching roller guarantees a defined seed placement and creates the seed-soil contact.

To achieve good results with this singulation technology, calibrated seed has to be used. Besides good sowing conditions the seed rate, too, is crucial. Experiences showed that sowing up to 250 grains/m² is optimum and can be carried out with the HORSCH SingularSystem.

To handle higher seed sizes and seed that cannot be singulated, e. g. coarse legumes, the SingularSystem coulter can be equipped with a special fall tube and can then be used like a “normal” seed drill without singulation.

With the Pronto 6 DC with double hopper two components can be applied on two horizons by means of the SingularSystem seed coulter with DoubleShot. Seed is placed with the Funck metering device or the stainless steel fall tube and via the DoubleShot system for example fertilizer is applied below. This is particularly advantageous for the early development of a lot of crops. Another advantage of the DoubleShot system is that in dry conditions there is no direct contact between fertiliser and seed and thus burns of the seedling can be avoided.