HORSCH Maestro Row Unit

In the two previous blog articles we already talked about the functioning and the design of our new metering unit generation AirVac and AirSpeed. This article will focus on our new Row Unit which can be equipped with both metering systems and will be used in all Maestro lines.

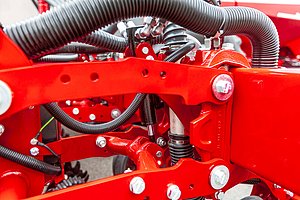

The most important yield factor in single grain sowing is a precise depth placement as well as the regular embedding of the grains to achieve a homogeneous emergence of the plant. Several components of the row unit influence the running performance of the unit and the precise depth control. The parallel connection of the seed units is a standard for single grain seed drills. Due to the parallelogram with a pendulum radius of 40 cm the HORSCH Maestro units can adapt to the soil and possible unevennesses in an optimum way. Moreover, the connection to the Maestros is very heavy and massive to guarantee stability even in most difficult conditions. With 35 cm the parallelogram of the HORSCH seed units is one of the widest on the market. And the wear points, that is the sleeves, too, are located very far at the outside. This is essential to absorb especially lateral or torsion forces at the unit in a better way and to keep the wear at the parallelogram and the unit connection as low as possible. Due to this durable, stable and maintenance-free design every Maestro can sow several thousand hectares.

In addition to the basic connection of the units at the frame the depth control of the seed discs, too, is essential for a precise depth placement of the grains. It is carried out by two depth control wheels which are controlled via the axle arms. The seed discs that are responsible for creating the seed furrow are attached right between the two depth control wheels. The seed depth is limited by the stop of the depth control plate. It can easily be adjusted via a pin. This design is maintenance-free. Large wear points at the connection of the depth control wheels guarantee high durability. Moreover, the depth control wheels as well as the seed discs are equipped with large and solid bearings so you do not have to compromise with regard to the depth placement in very difficult and hard conditions after a long service performance of the machine.

In addition to the connection of the unit and the design of the depth control the coulter pressure is essential for the precise embedding of the grain. As a standard, the Maestro row units are equipped with hydraulic cylinders that transfer pressure to the coulters. Thus, the driver can adjust the coulter pressure from 150 kg to a maximum of 350 kg per row – quite comfortable in the cabin. But usually the HORSCH Maestro is equipped with the AutoForce. AutoForce is a system that automatically adapts the coulter pressure to the prevailing soil conditions while driving in the field. In case of changing soil conditions, the system chooses the coulter pressure that guarantees the safe penetration of the seed coulters into the soil. Thus, the adjusted seed depth is always maintained. There is no risk that the seed unit moves too shallowly or even above the soil because the coulter pressure is too low. The system also prevents unnecessary soil compaction in the area of the seed slot which can be caused if the coulter pressure is too high. These compactions can have a negative effect on the root growth and the youth development especially in wet sowing conditions.

To adapt the seed units individually it is possible to mount various closing wheel systems according to the prevailing soil conditions. You can either go for 50 mm wide press wheels with a smooth or profiled surface or for 25 mm narrow rubber press wheels. Moreover, HORSCH developed two special press wheels made of cast iron. These finger and spike press wheels are always mounted in combination with a normal rubber press wheel which carries out the depth control. The special press wheels break open the seed slot wall and guarantee a slight soil compaction that is created when the seed slot is opened by the two seed discs. The wheels also improve the closing of the seed furrow and especially in very heavy clay soils prevent it from opening again in dry conditions. Moreover, the targeted loosening of the soil by the special press wheels encourages the root growth and thus the youth development of the plants. The finger resp. spike press wheel always runs at the side of the seed furrow where the underground fertilisation band is located. Thus, the roots of the plants can grow faster and freely towards the fertiliser depot. The finger press wheel is the more aggressive of the two press wheels and is used in hard conditions on heavy and medium soils. The spike press wheel is less aggressive and is ideal for medium soils as well as for light conditions.

The new Maestro single grain seed drills have been designed for durability and stability. You can choose between the two metering systems and from various equipment options, thus the single grain seed drill HORSCH Maestro can be adapted to the conditions of the site, the farm-specific requirements and the individual range of application in an optimum way. HORSCH always focusses on the optimum embedding of the grains, the establishment of homogeneous populations and the encouragement of the youth development.