Getting a crop planted at the correct time, at the correct depth, and in the correct environment are the fundamental keys in setting a stage for maximum yield potential. These are the key fundamentals that Maestro row crop planter technology are based on. Technology and design that maximize every minute of the optimum planting window to secure maximum potential yield. A complete design concept to ensure precise placement of each seed to achieve rapid germination and uniform emergence. This is a platform that protects soil structure integrity during planting. The Maestro row crop planter is the only planter on the market today with a common-sense approach in design that incorporates basic agronomic principals for securing maximum yield potentials. We use three terms to describe this unit - simple, robust, precise.

Timing

For spring planted crops, no matter where in the world, there is a 10-14 day planting window of opportunity to secure maximum yield potentials. If crop is planted after that optimum window yield losses will result not because of fertility, seed variety, or planter brand but simply because of the calendar. The Maestro SW planter chassis is designed with this in mind. Capacity is key in securing more planted acres per day especially when in variable field conditions. Large seed and liquid fertilizer carrying capacities allow for more planting time and less filling time. Pending seedbed conditions, planting speed can be increased beyond normal speeds to capitalize further on more planted acres per day within the optimum window.

Seed Placement

Precise seed depth placement has significant impact on yields, both positive and negative. Placing each seed at a proper depth, into moisture, and properly closing the furrow promotes rapid germination along with uniform emergence. This is a fundamental key in setting the stage for maximum yield potentials. Shallow placed seed often has higher mortality or delayed emergence due to lack of moisture. Seed placed too deep can become victim to cold soil temperatures, experience delayed emergence, and fall behind in yield potential. Precise seed placement is a full system approach in the Maestro SV. To place a seed precisely first starts with stabilizing the toolbar, the weight transfer system on the Maestro SV distributes the chassis weight over the width of the toolbar, thus stabilizing it. With each row unit featuring standard hydraulic downforce, the row unit can be engaged into the soil with up to 770 pounds of downforce without worry of the toolbar lifting. Beyond keeping the row unit secured at desired depth, the disc opener of the row unit must be kept consistently and at a perpendicular angle to maintain a proper seed furrow. Solid parallel arm shaft design on front of the row unit ensures the row unit maintains a consistent perpendicular engagement angle.

Advantages

- Complete concept for maximizing planted acres per day, precision seed placement, along with maintaining uniform and consistent seedbed soil structure.

- Largest seed / fertilizer carrying capacities available in the market today.

- Up to 249 bushel seed carrying capacity (pending model).

- Up to 1225 gallons of liquid fertilizer capacity (pending model).

- Global industry first and leading technology in electric meter drives, weight transfer, and hydraulic downforce technologies.

- Electric drive meters precisely singulate seed while having the ability for variable rate planting, individual row shutoff and curve compensation.

- Chassis system designed for large product carrying capacity while having a light footprint.

- Lightest soil footprint in the industry – large diameter tires, large footprint, low tire psi.

- Light soil footprint in combination with weight transfer system aids in elimination of yield robbing pinch rows.

- Weight transfer system stabilizes the toolbar, thus resulting in superior stabilization of row units for precise depth control.

- More high performance features as standard equipment than any other planter on the market.

- ISOBUS implement control allows use of industry or HORSCH virtual terminals for planter operation and precision farming tasks.

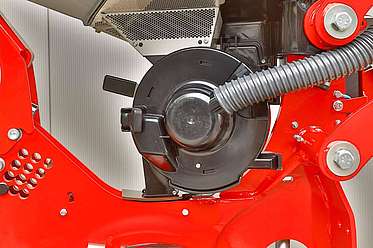

Row Unit Composition

The HORSCH Maestro SV utilizes the strongest built row unit in the industry, which has been proven globally for superior agronomic performance, low maintenance, and low wear characteristics. Several key design parameters ensure long life of the row unit along with precision placement. Parallelogram design integrity is absolutely necessary for precise, consistent, perpendicular engagement of the double disc opener. Indexed depth setting which eliminates the need to “calibrate” each row for depth and ensures precise seed placement. Precision machined row bodies with hydraulic downforce result in consistent singulation and ride quality keeping the meter steady, and the seed release tried and true.

Industry first and industry leading frame weight distribution system aids in eliminating pinch rows, along with stabilizing the toolbar. This feature ensures the toolbar stays parallel to the seedbed no matter the row unit downforce required. This technology eliminates additional weight needed on the wings to hold wings down. Also, when using hydraulic downforce on the row unit, a stable and firm positioned toolbar is needed to apply downforce. Downforce can be adjusted in-cab or automatically on-the-fly through the AutoForce System. The hydraulics eliminate the chatter and bounce to the row unit caused by other downforce systems with springs or other competitive technologies. By creating a smooth ride, singulation integrity is preserved and the row unit maintains downforce and precise soil engagement for consistent seed depth placement.co

Capacity

The Maestro SV series is a complete high-efficiency planting concept built from the ground up for capacity and increased planted acres per day. Its industry leading seed and liquid fertilizer capacity (166/249 bushel seed) (725/1225 gallon liquid) contributes to more time planting and less time filling. Available with the Maestro SW Deluxe is an additional saddle tank option supplying an additional 500 gallons of liquid capacity. The Maestro SV planter has been a globally proven concept to achieve more planted acres per day than same or larger size competitive planters. By maximizing planted acres per day and the planting window of opportunity, Maestro SV secures maximum yield potentials.

Furrow Integrity

Maintaining uniform soil structure at planting time gives each seed equal chance to reach maximum yield potential. If soil structure is restrictive, the crop yield is restricted. The Maestro SW uses large tires with a light soil footprint along with the weight transfer system to minimize compaction on headlands and aid in eliminating pinch rows. Pinch row compaction can have significant yield impacts, especially in wet planting seasons. Eliminating this compacted zone secures your maximum potential yields. Another advantage with the large tires is maneuverability in variable soil conditions. Compaction will be significantly reduced while maneuvering in the field.

TECHNICAL SPECIFICATIONS

| Maestro SV 5800 | 1630 Liquid | 1630 Seed Only | 2420 Liquid | 2420 Seed Only |

| Fold | Front Fold | Front Fold | Front Fold | Front Fold |

| Total Weight | 21,000 lb | 21,000 lb | 24,000 lb | 24,000 lb |

| Axle Weight | 16774 lb | 16774 lb | 19170 lb | 19170 lb |

| Hitch Weight | 4,226 lb | 4,226 lb | 4,830 lb | 4,830 lb |

| Wheel Base | 20 ft | 20 ft | 20 ft | 20 ft |

| Transport Width: Singles (Duals)[Tracks] | 12 ft 6 in (17 ft 6 in) | 12 ft 6 in (17 ft 6 in) | 12 ft 6 in (15 ft 1 in) | 12 ft 6 in (15 ft 1 in) |

| Shipping Width Minus Tires (Duals)[Tracks] | 11 ft 9 in (13 ft 4 in) | 11 ft 9 in (13 ft 4 in) | 11 ft 9 in (12 ft 5 in) | 11 ft 9 in (12 ft 5 in) |

| Shipping Height Minus Tires | 12 ft | 12 ft | 12 ft | 12 ft |

| Transport Height | 12 ft 9 in | 12 ft 9 in | 12 ft 9 in | 12 ft 9 in |

| Transport Length | 25 ft 8 in | 25 ft 8 in | 26 ft 2 in | 26 ft 2 in |

| Toolbar Size | 10 in x 8 in | 10 in x 8 in | 10 in x 8 in | 10 in x 8 in |

| Seed Tank Size | 83 Bushel | 2 - 83 Bushel (166 Bushel) | 83 Bushel | 2 - 83 Bushel (166 Bushel) |

| Fertilizer Tank Size | 725 Gal | N/A | 725 Gal | N/A |

| Pump Size | 92 GPM Max | 92 GPM Max | 92 GPM Max | 92 GPM Max |

| Pump Type | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Wing Flex | Up/Down 20 Degree | Up/Down 20 Degree | Down 10 Deg, Up 20 Deg | Down 10 Deg, Up 20 Deg |

| Parallel Arm Length | 14-3/8 in | 14-3/8 in | 14-3/8 in | 14-3/8 in |

| Parallel Arm Thickness | 7/16 in | 7/16 in | 7/16 in | 7/16 in |

| Row Unit Travel | 10 in | 10 in | 10 in | 10 in |

| Opener Disc Angle | 12 Degree | 12 Degree | 12 Degree | 12 Degree |

| Opener Disc Diameter | 15 in | 15 in | 15 in | 15 in |

| Opener Disc Thickness | 3.5mm | 3.5mm | 3.5mm | 3.5mm |

| Opener Bearing Type | Double Ball Bearing | Double Ball Bearing | Double Ball Bearing | Double Ball Bearing |

| Service Points | 70 | 70 | 102 | 102 |

| Number-Size of Tires Transport | 2-520/85R42 (4-520/85R42) | 2-520/85R42 (4-520/85R42) | 2-480/80R46(4-320/90R54) | 2-480/80R46(4-320/90R54) |

| Number/Size of Tires Wings | 2-14.9-24 | 2-14.9-24 | 2-14.9-25 | 2-14.9-25 |

| Row width Configurations | 30 in | 30 in | 20 in | 20 in |

| Hydraulic Requirements | 50 GPM | 50 GPM | 50 GPM | 50 GPM |

| Electronic Requirements | 35 Amps | 35 Amps | 50 Amps | 50 Amps |

| Max Down Pressure | 770 lb | 770 lb | 770 lb | 770 lb |

| Maestro SV Standard | 2422 Liquid | 2422 Seed Only | 3115 Seed Only | 3215 Seed Only |

| Fold | Front Fold | Front Fold | Front Fold | Front Fold |

| Total Weight | 27,500 lb | 27,500 lb | 27,000 lb | 27,000 lb |

| Axle Weight | 21966 lb | 21966 lb | 21566 lb | 21566 lb |

| Hitch Weight | 5,534 lb | 5,534 lb | 5,434 lb | 5,434 lb |

| Wheel Base | 24 ft | 24 ft | 20 ft | 20 ft |

| Transport Width: Singles (Duals) [Tracks] | (16 ft 3 in)[14 ft 10 in] | (16 ft 3 in)[14 ft 10 in] | (12 ft 6 in) [17 ft 6 in] | (12 ft 6 in) [17 ft 6 in] |

| Shipping Width Minus Tires (Duals)[Tracks] | (13 ft 9 in)[14 ft 10 in] | (13 ft 9 in)[14 ft 10 in] | (11ft 9 in) [13 ft 4 in] | (11ft 9 in) [13 ft 4 in] |

| Shipping Height Minus Tires | 12 ft 4 in | 12 ft 4 in | 12 ft 8 in | 12 ft 8 in |

| Transport Height | 13 ft 5 in | 13 ft 5 in | 13 ft 5 in | 13 ft 5 in |

| Transport Length | 33 ft 6 in | 33 ft 6 in | 27 ft | 27 ft |

| Toolbar Size | 10 in x 8 in | 10 in x 8 in | 10 in x 8 in | 10 in x 8 in |

| Seed Tank Size | 83 Bushel | 2 - 83 Bushel (166 Bushel) | 2 - 83 Bushel (166 Bushel) | 2 - 83 Bushel (166 Bushel) |

| Fertilizer Tank Size | 730 Gal | N/A | N/A | N/A |

| Pump Size | 92 GPM Max | 92 GPM Max | 92 GPM Max | 92 GPM Max |

| Pump Type | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Wing Flex | Down 3 Deg, Up 20 Deg | Down 3 Deg, Up 20 Deg | Down 3 Deg, Up 20 Deg | Down 3 Deg, Up 20 Deg |

| Parallel Arm Length | 14-3/8 in | 14-3/8 in | 14-3/8 in (22-3/8 in) | 14-3/8 in (22-3/8 in) |

| Parallel Arm Thickness | 7/16 in | 7/16 in | 7/16 in | 7/16 in |

| Row Unit Travel | 10 in | 10 in | 10 in (15-3/8 in) | 10" (15-3/8 in) |

| Opener Disc Angle | 12 Degree | 12 Degree | 12 Degree | 12 Degree |

| Opener Disc Diameter | 15 in | 15 in | 15 in | 15 in |

| Opener Disc Thickness | 3.5mm | 3.5mm | 3.5mm | 3.5mm |

| Opener Bearing Type | Double Ball Bearing | Double Ball Bearing | Double Ball Bearing | Double Ball Bearing |

| Service Points | 126 | 126 | 130 | 130 |

| Number-Size of Tires Transport | 4-IF380/90R46 | 4-IF380/90R46 | 2-520/85R42 (4-520/85R42) | 2-520/85R42 (4-520/85R42) |

| Number/Size of Tires Wings | 2-14.9-25 | 2-14.9-25 | 2-14.9-27 | 2-14.9-27 |

| Row width Configurations | 22 in | 22 in | 30 in/15 in | 30 in/15 in |

| Hydraulic Requirements | 50 GPM | 50 GPM | 50 GPM | 50 GPM |

| Electronic Requirements | 50 Amps | 50 Amps | 64 Amps | 64 Amps |

| Max Down Pressure | 770 lb | 770 lb | 770 lb | 770 lb |

Features

Industry leading weight distribution system

- Beyond eliminating pinch rows, the weight distribution system also stabilizes the toolbar.

- Toolbar stays parallel to the seedbed no matter the row unit downforce required.

- No additional weight needed on the wings to hold them down.

- When using hydraulic downforce on the row unit, a stable and firm positioned toolbar is needed to push up against.

Industry leading hydraulic downforce on the row unit

- Each row unit comes standard with a hydraulic cylinder for applying downforce.

- Downforce can be adjusted in-cab or through the AutoForce System.

- Hydraulics eliminate the chatter and bounce to the row unit caused by competitive downforce systems.

- By creating a smooth ride, singulation integrity is preserved.

- Row unit maintains downforce and precise soil engagement for consistent seed depth placement.

Strongest row unit in the industry

- Proven globally for superior performance, maintenance and wear.

- Designed for long life.

- Parallelogram Integrity provides superior durability.

- Absolutely necessary for precise, consistent, perpendicular engagement of the double disc opener.

- Designed for strength and precision.

Indexed Depth Setting

- No need to “calibrate” each row for depth.

- Precision machined row bodies.

Consistent Singulation

- Ride quality maintained to keep meter steady, maintaining seed release accuracy.